- Well-understood course

A Course to Better Understand Printing and Marking

- Printing and marking

Principle of Character Marking

The pencil guns arranged in linear is moving relatively on the surface of object with constant distance and sprays paint dots to form characters. Spray timing of each gun is commanded from the marking controller, which edits marking data from host computer into matrix formation.

arge characters and small characters can be marked simultaneously by one marking head.

Printing device product

Principle of Identification Marking

Identification Marking Equipment performs one point marking or line marking at the designated position according to the command from the controller. Two types of paint gun are used.

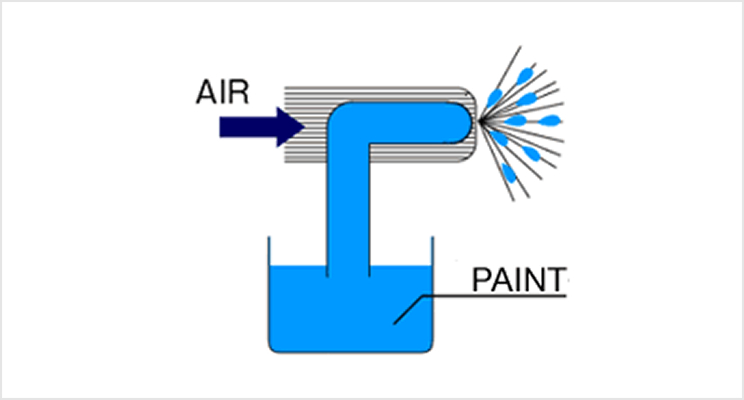

Spray Gun Type

Paint is sucked and atomized by air discharged from duplex nozzle and sprayed to the surface of object.

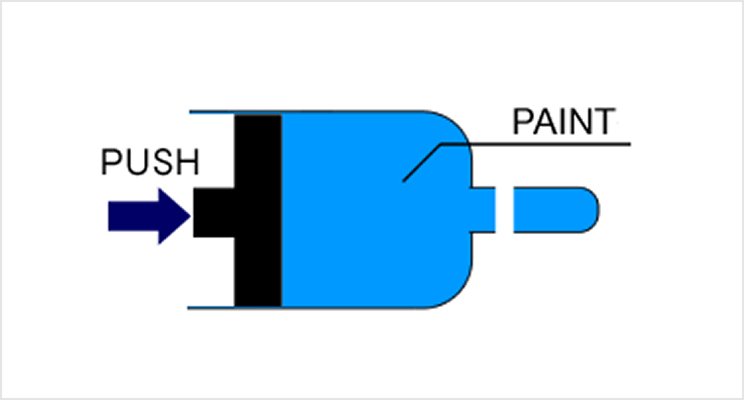

Squirt Gun Type

Paint is pressurized by solenoid driven piston and shot from nozzle.

a) Spray Gun Type

b) Squirt Gun Type

Marking device product

Principle of Stamping

Principle of Micro-percussion (pneumatic stylus) Type Stamping

Micro-percussion hardened stylus indents the surface of the material and marks characters and logos.The micro impact causes minimum stress on the material.

The principle of revolving stamping

The rotating head that does the marking consists of a stamping (rod) that is fixed by a spring. The rotating head is driven and controlled so that the front of the impact cylinder is at a predetermined position. The cylinder then instantly activates the stamping machine to stamp the characters.

IJPの原理

The ink ejected from the nozzles of the print head is vibrated, atomized, and simultaneously charged. As the ink particles pass through the deflection electrode plates, their flight direction is altered for each particle, enabling printing.