Test method

Ultrasonic testing is a method to irradiate ultrasonic wave to the object to confirm presence of internal flaws, etc.

Also, it can be utilized in various scenes including measurement of wall thickness or measurement of thickness/length, etc.

Materials covered in the testing

- Metallic and non-metallic material

Products used

- Ultrasonic flaw detection equipment

- Contact medium

Features of testing

feature

Most suitable for in-line inspections as the inspection results are obtained immediately

feature

Most suitable for inspections for simple shapes

feature

It can also be applied to measurement of wall thickness or measurement of thickness/length

feature

It is possible to conduct inspections safely (compared to RT)

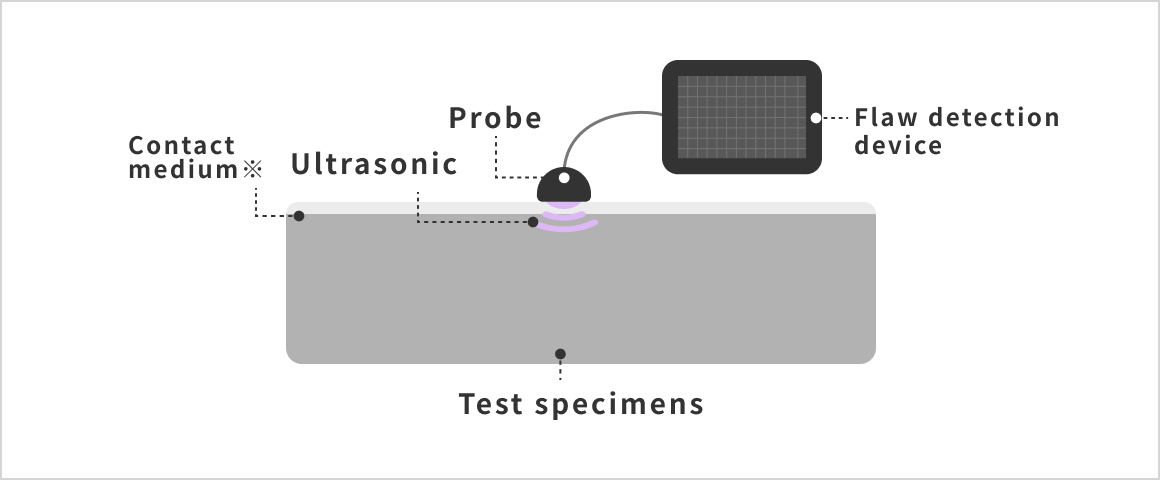

Flow of flaw detection

Ultrasonic testing is generally conducted by the following procedure.

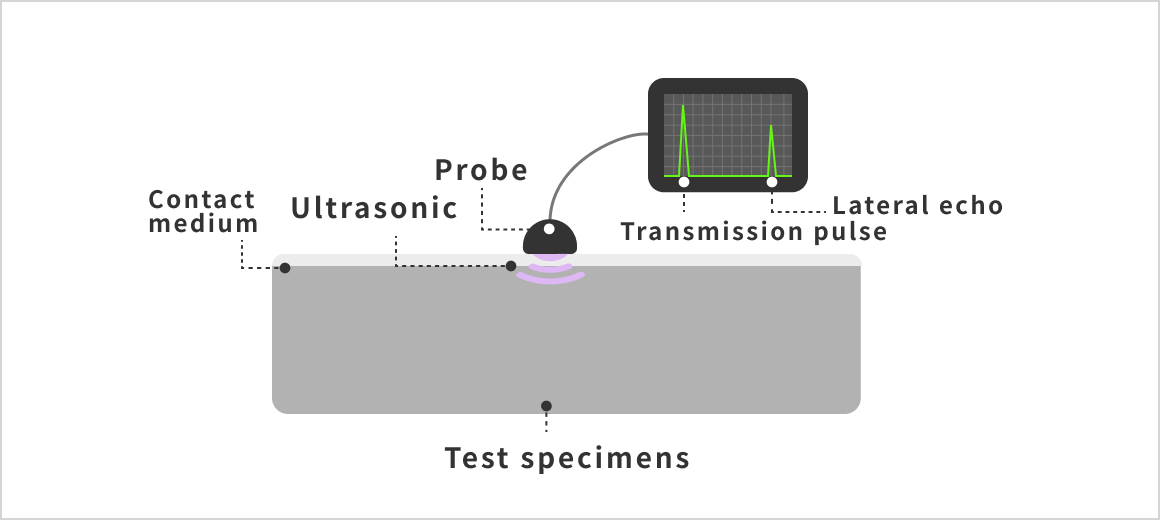

By emitting ultrasonic waves from a probe, it is possible to check for defects inside the test specimen*.

*In order to efficiently transmit the ultrasonic waves emitted from the probe, it is common to apply a contact medium such as water or oil between the test specimen and the probe.

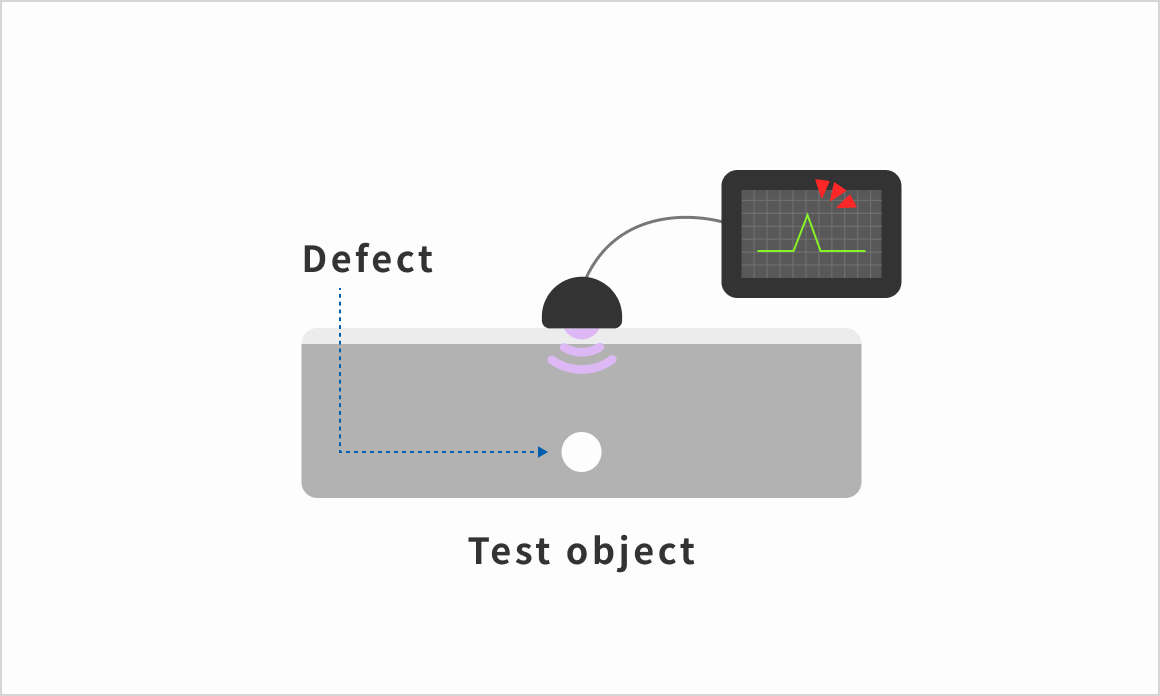

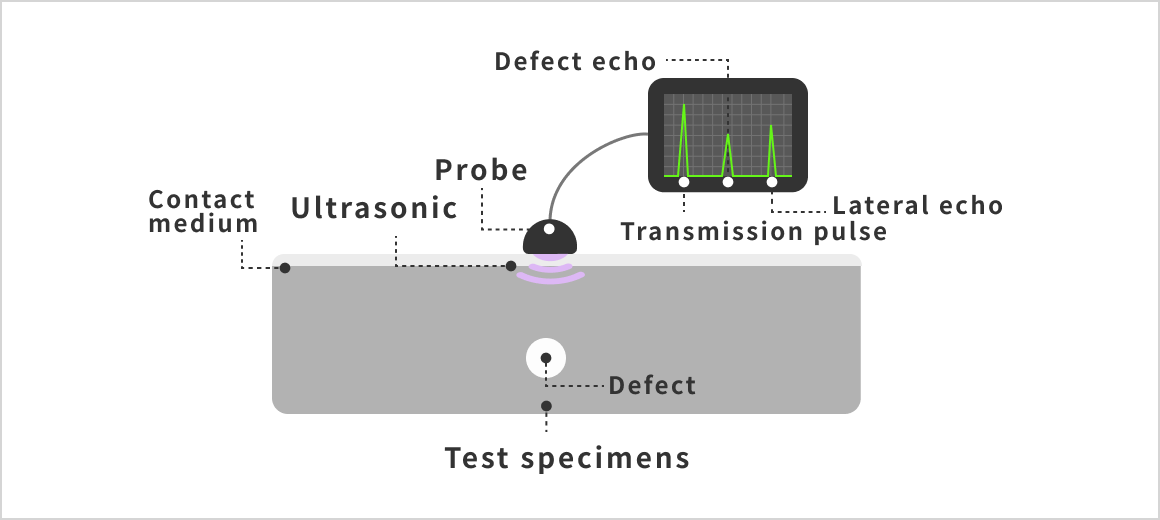

In case of defects

If there are no internal defects, no signal will be displayed between the transmission pulse and the bottom echo.

In case of no defects

If there is an internal defect, a signal will appear between the transmission pulse and the bottom echo. From this signal, it is possible to estimate the location and size of the defect.

Product Lineup

UI-S9

Features

- There are various choices available to meet your needs.

Selection example

- Portable type with excellent portability / operability: IPX6 compatible

- Automatic ultrasonic inspection system optimized for each part to be inspected

Product Specifications

The 6.5 ”high-brightness LCD ensures waveform recognition in fine weather outdoors.

Easy data storage to PC using USB memory.

Adjustable to an easy-to-see angle by the stepless stand.

Convenient to carry with the upper hand strap.(Option)

UI-S9 adopts lithium ion battery.

(Continuous operation about 8 hours)

Use

Material flaw detection

Ultrasonic Nondestructive Testing to Detect Internal Defects in Round Bars, Pipes, Flat Plates, Grinding Stones, and Glass

Weld inspection

Spot welds, Laser welds, Rebar welds (Structures), Automatic welds (Bridges, Pressure vessels, etc.) Gas pressure welds, Rail pressure welds , Rail standard welds, Extremely thick welds

Thickness measurement

Container bottom plate corrosion wastage measurement Various piping corrosion wastage measurement

Thickness / Length measurement

Thickness measurement Lock bolt / Anchor bolt length measurement (fixed length inspection)

Fusion / Adhesion detection

Detection of non-fusion area / Detection of unwelded area

Propagation time measurement

Application to cable deterioration diagnosis, etc.

Education support

Use at School / Research laboratory / Educational institution

Automatic ultrasonic inspection equipment for automotive parts

Features

Automatic ultrasonic inspection system can be customized for each inspection target part.

Please contact our sales for details.

Proposed system

Automatic inspection system

Inspection example

Inspection target :

Material, Cast metal, Transmission

Proposed system

Inspection target :

Engine head fixing bolts

Inspection example

Bolt axial force gauges UI-27AF

Probe (ultrasonic probe)

Features

We provide a broad range of probes.It is possible to provide and make a proposal according to the inspection conditions.

Product lineup

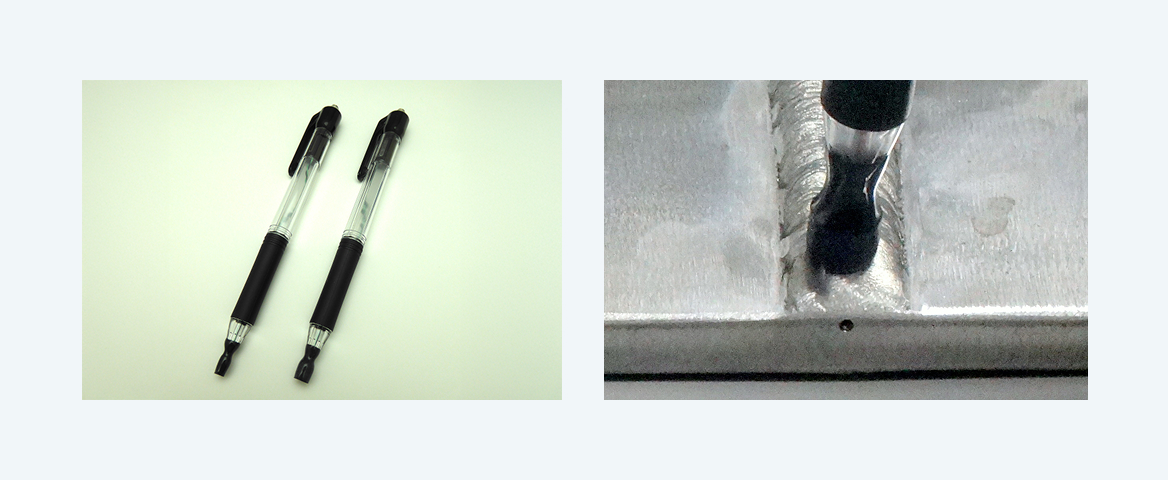

Ultrasonic Soft Transducer “JUTAN”

A probe that fits flexibly to rough surfaces, corrugated surfaces, narrow and distorted parts, etc.

It is possible to directly contact to inspect welded parts, narrow grooves, and gas-cutting surfaces.

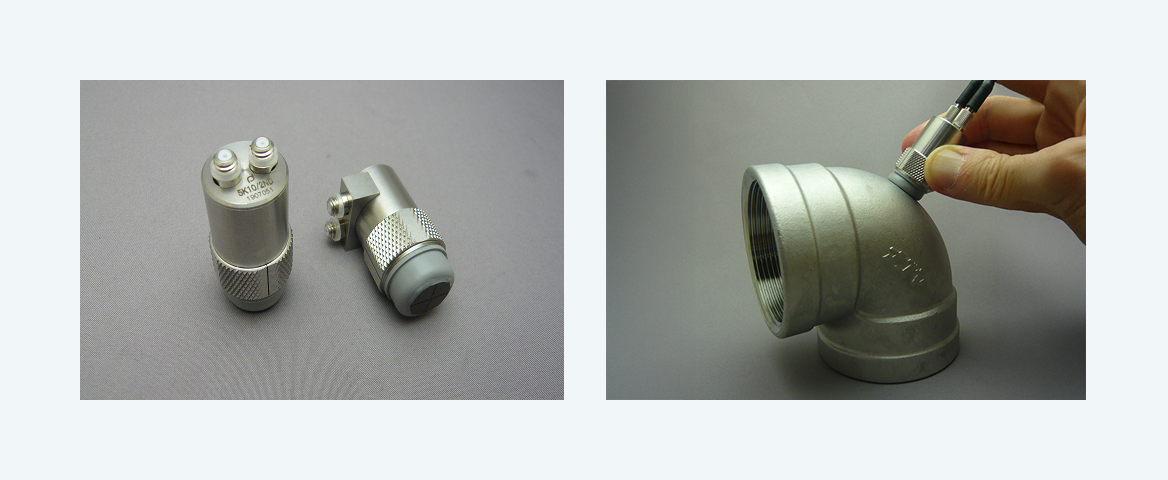

Ultrasonic Flexible Transducer “TAKOTAN

A probe with flexibility (property to flexibly bend).

It is possible to conduct inspections by fitting it to three-dimensional curved surfaces to inspect surfaces like an octopus.

Ultrasonic Flexible Linear Array Transducer “KYOKUTAN”

A flexible array probe that fits not only to flat surfaces but also to curved surfaces and corrugated surfaces.

Ultrasonic Dry Couplant & Flexible Type “KANTAN”

A dry coupling probe requiring no contact medium.A dry coupling probe that requires no contact medium and can be used on clean flat surfaces and curved surfaces.Inspecting objects don’t getwet or dirty by it.

Ultrasonic Soft Transducer “JUTAN”

Ultrasonic Flexible Transducer “TAKOTAN”

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30