Test method

Radiographic testing is a method to confirm presence of flaws inside the test specimen by irradiating radioactive rays (X-rays or γ-rays, etc.).

It is also possible to apply it to applications such as thickness measurement or different material determination of test specimens by utilizing its property that the penetration rate of radioactive ray varies depending on the material character or density of test specimen.

Materials covered in the testing

- Metallic and non-metallic material

Products used

- X-ray CT device

Features of testing

feature

It takes time to obtain inspection results.

feature

Available for inspection objects of any materials or shapes

feature

It can also be applied to different material determination or dimension measurement by utilizing the X-ray CT

feature

Requires license/notification and safety measures as it uses X-rays

Types of radiographic testing

For the testing using radioactive rays, “Penetrating X-rays” and “X-ray CT” are available.

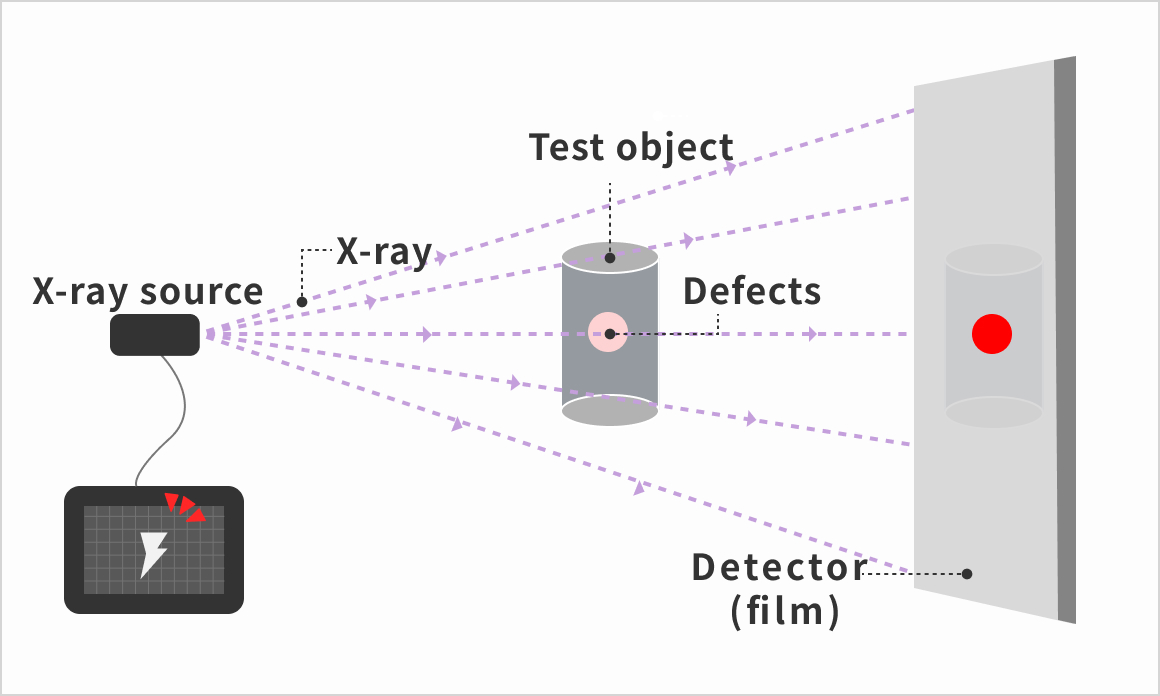

Penetrating X-rays

Irradiate X-rays from one direction and conduct two-dimensional imaging.

Observe the result of imaging by printing it on a film, etc.

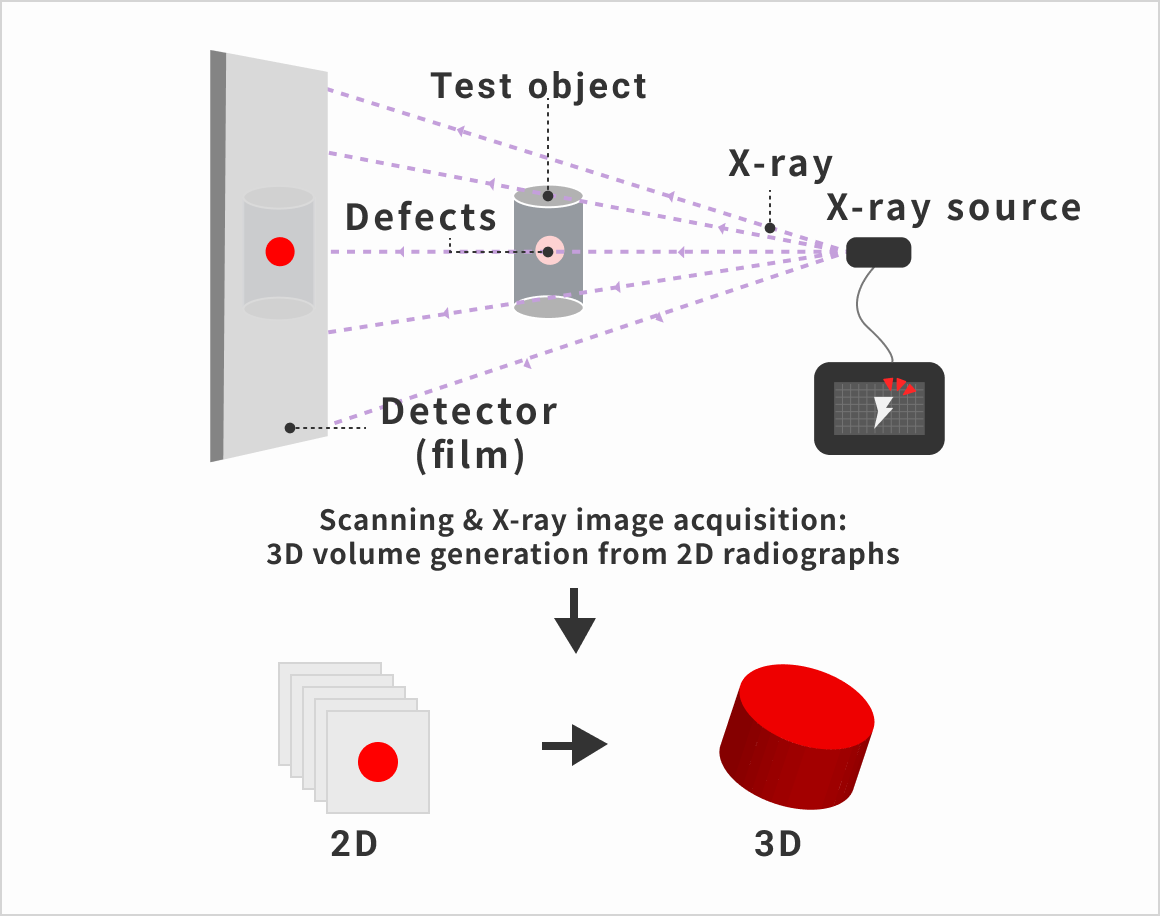

X-ray CT

Irradiate X-rays while rotating, and conduct three-dimensional imaging upon reconstituting on the software.

The dedicated software is used to observe the imaging result.

Flow of flaw detection

Radiographic testing is generally conducted by the following procedure.

X-ray irradiation

X-rays are emitted from the X-ray source and captured by an X-ray detector placed directly opposite the target object. The test specimen or the X-ray device itself rotates to obtain X-ray projection images from multiple angles (collecting data on different cross sections of the object).

Measurement

It measures the intensity of radiation after X-rays pass through an object (different materials and densities in the object absorb or scatter X-rays differently).

Reconstruction

Based on the numerous X-ray projection images collected, 3D volume data is reconstructed using specific algorithms.

Analysis

The resulting 3D data is then analyzed using specific software. You can get information about the internal defects, dimensions, shape, composition, etc. of the part.

Product Lineup

- X-ray inspection device

X-ray CT device

We propose the X-ray CT device that enables the most suitable testing, upon hearing of the customer’s desire.

Features

- Equipped with a high-output X-ray tube with a maximum output of 450 kV/15 mA

- Can generate low-noise CT images with fan beam CT

- Achieves high-speed CT imaging with optional cone beam CT

- Enables noiseless imaging even with composite products, such as products made of resin and metal, with a 16-bit line sensor

Use

- Inspection of internal defects

- Thickness analysis

Product Specifications

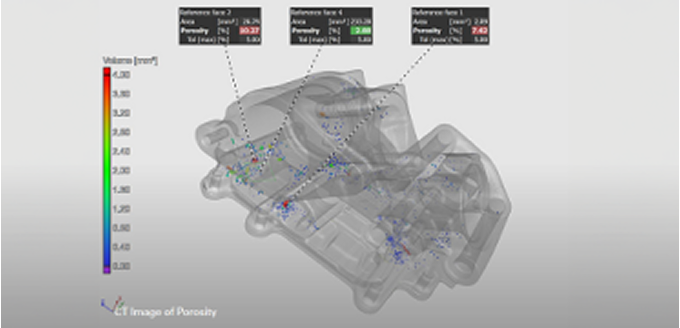

Example of CT system functions : Defect analysis

As CT possesses X, Y, and Z coordinate information, defects can also be displayed by volume. The size of any defects is also displayed as a color map, and the distribution of defects in the workpiece can be observed intuitively.

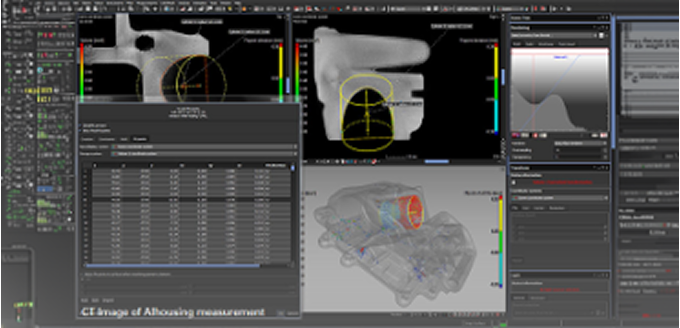

Example of CT system functions : Coordinate measurement

For a conical or cylindrical workpiece, the deviation between axes at the center of any space can be calculated automatically.The High-Output X-Ray CT System can also take various measurements such those of distance, angle, roundness, coaxiality, diameter, parallelism, and flatness.

The basis of measuring is the surface accuracy of the material, and the following two points are points that improve the accuracy of measurements:

Sufficient permeability (450 kV or more)

An LDA sensor (X-ray receiver) that does not cause distortion in the image *Line detector

Contracted inspection service

with X-ray CT device

We provide the “Contracted inspection service with X-ray CT scanning” to satisfy the needs for the spotted use of X-ray CT device.

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30