Product Description

Introduction of magnetic particle equipment is common in the case of mass inspection of mass produced items, etc.

For casted and forged objects made from ferromagnetic materials (irons, etc.), MARKTEC can propose the equipment that meets the customer’s desire.

Details of product

Magnetic particle equipment (for general industry)

Magnetic particle equipment (for steel industry)

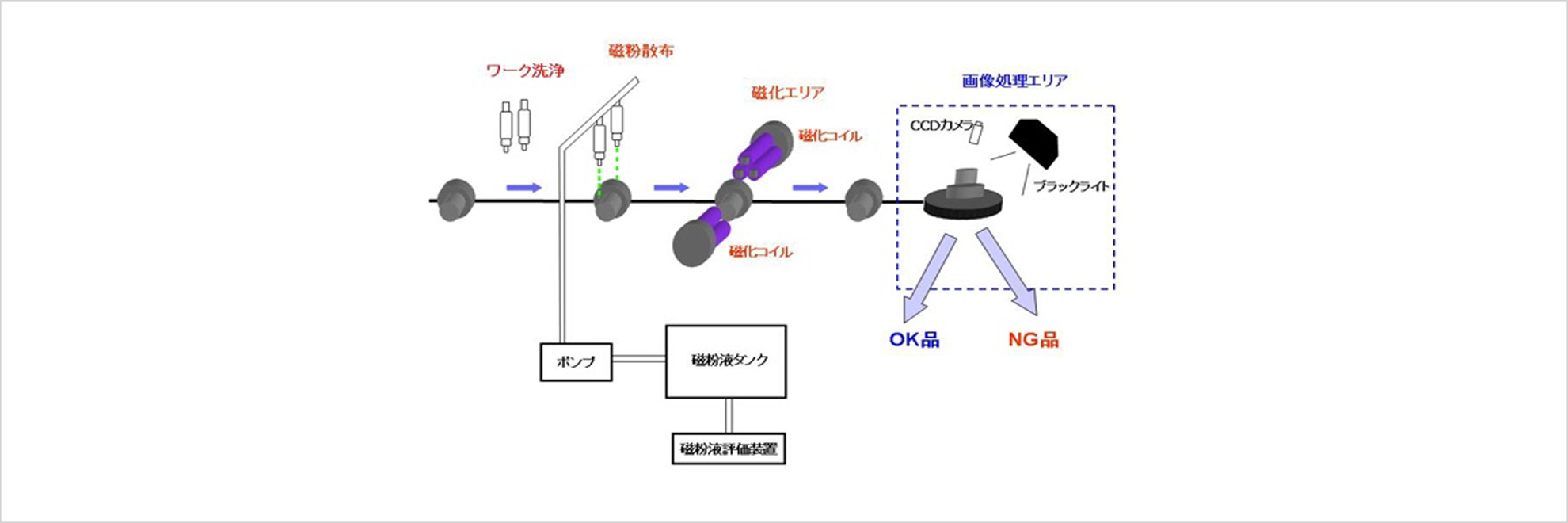

Full-automatic magnetic particle equipment for automotive parts

Features

- By adopting the magnetic particle liquid evaluation equipment, management of magnetic particle liquid becomes consistent and inspection conditions becomes consistent.

- It is possible to prevent human errors as the pass/fail decision becomes consistent by adopting the image processing.

- It is possible to reduce the number of inspection man-hours as the traveling/contactless inspection becomes available by adopting the triple-pole coil

Flaw detection process image

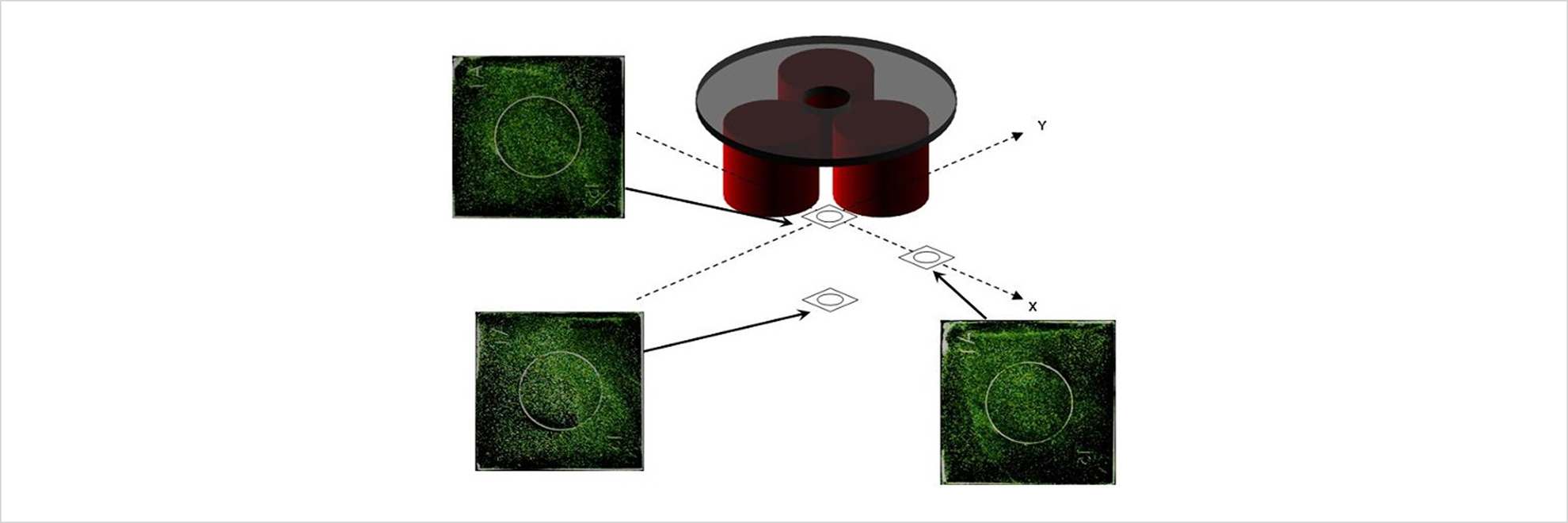

Triple-pole coil magnetic particle equipment

Features

- It is possible to detect flaws in the longitudinal (L) and circumferential (T) directions simultaneously by generating the rotating magnetic field with the triple-pole coil.

- Sparks that damage the work do not occur upon inspection because the flaw detection is conducted in a contactless manner.

- Significant reduction of cycle time is possible because it done in the traveling magnetizing method.

- MARKTEC can design and fabricate the flaw detection systems corresponding to various inspection parts.

Image figure

Horizontal wet-type magnetic particle equipment

Features

- MARKTEC can design and fabricate the stationary-type magnetic particle equipment for general purpose that conforms to standards such as JIS and ISO.We provide a lineup of single magnetization method and composite magnetization method.

Single magnetization method (SUA series)

It detects flaws in a single direction.

| Type | SUA-35 | SUA-66 | SUA-138-A | SUA-244-B |

|---|---|---|---|---|

| Distance between electrodes | 350mm | 660mm (26inch) | 1380mm (54inch) | 2440mm (96inch) |

| Max. magnetizing current | AC1000A・DC500A(single phase half-wave rectifi cation) | AC2500A・DC1500A(single phase half-wave rectifi cation) | AC2500A・DC6000A (3phase ful-wa ve rectifi cation) | |

| Magnetizing time | 0.1 ~3.0sec(set by timer) | “0.1 ~3.0sec (set by timer)” or “free setting selectable” | ||

| Demagnetizing method | – | – | AC Current attenuation Approx. 5 sec | AC・DC Current attenuation AC:5sec・DC:30sec |

| Coil | 150φ Coil as auxiliary | 300φ Coil stationary type | ||

| Coil magnetizing power | AC6000AT DC3000AT | AC15000AT DC9000AT | AC15000AT DC36000AT | |

| Approx.30A | Approx.150A | Approx.250A | Approx.350A | |

| Unit dimension | W820×D1300×H1340mm | W1400×D1300×H2200mm | W2200×D1300×H2200mm | W3250×D1300×H2200mm |

| Black-Light (Super-Light E-40L) | 1 set | 1 set | 2 set | 3 set |

※Magnetizing current value: AC=actual value, DC=average value

Composite magnetization method (SUB series)

It is possible to detect flaws in all directions by conducting flaw detection while switching the magnetizing direction automatically.

| Type | SUB-66 |

|---|---|

| Distance between electrodes | 660mm(26inch) |

| Magnetizing current | AC+AC、AC+DC(single phase half-wave rectification)、DC(single phase half-wave rectification)+DC(single phase half-wave rectification) |

| Max. magnetizing current | AC2500A、DC1500A(single phase half-wave rectification) |

| Magnetizing time | 0.1 ~3.0sec(set by timer) |

| Magnetizing method | Axial current method + Coil method |

| Demagnetizing method | |

| Power supply | AC 3phase、200/220V、50/60Hz、Approx.150A |

| Unit dimension | W1500× D1300× H2200mm |

| Black-Light | Super-Light E-40L (1set) |

※Magnetizing current value: AC=actual value、DC=average value.

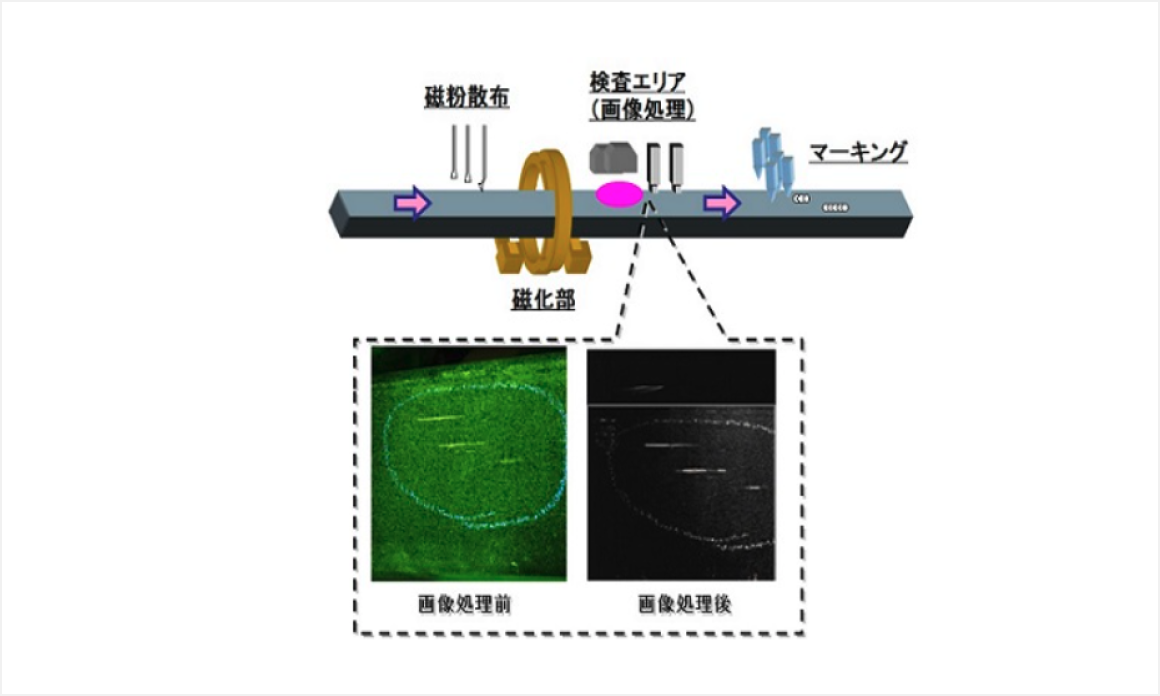

Full-automatic magnetic particle equipment Super-Line Magna

Features

- It is a fully-automatic magnetic particle equipment integrating the image processing device and the marking device.

- Efficient inspection is realized by detecting the flaws in the longitudinal direction (L) and the circumferential direction (T) at the same time.

- Flaw map data is output by dividing billets by the units of 100 mm in the longitudinal direction (L) and 20 mm in the circumferential direction (T).

- Available standard flaw detection speed is 40 m/min (Max. 60 m/min).

Flaw detection process image

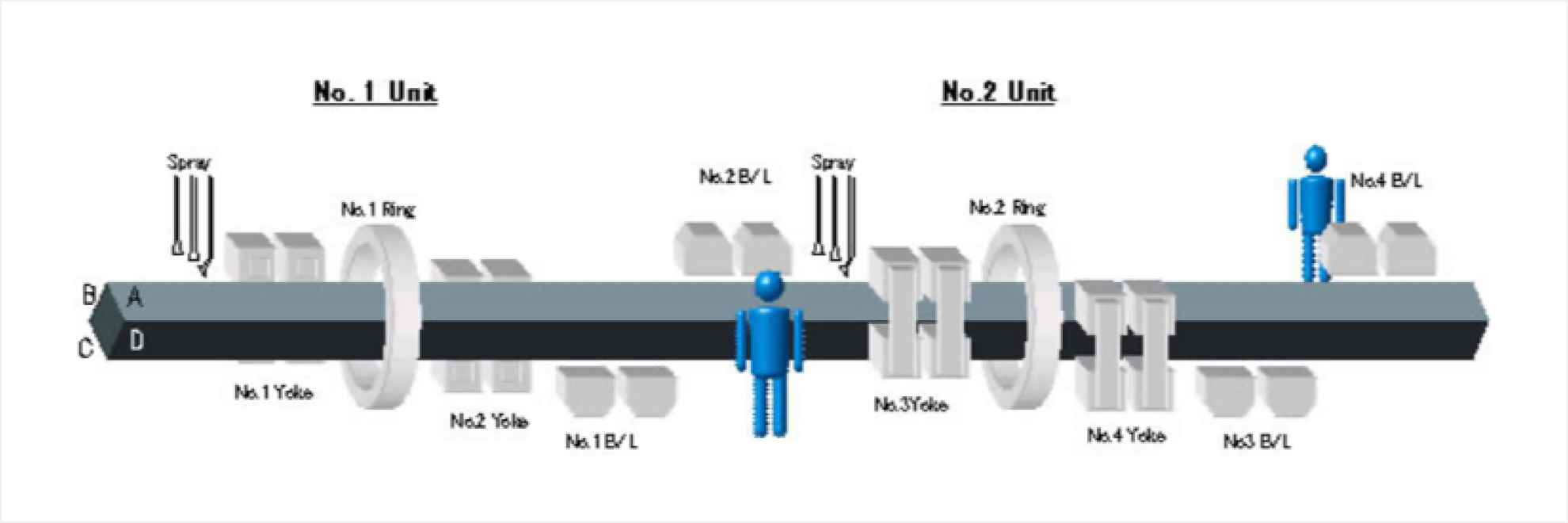

Magnetic particle equipment for billets Line-Magna

Features

- Reduction of equipment cost is possible because flaws on the surfaces of billets can be inspected during feeding and space for installation is not required.

- Inspection is possible on four surfaces at the same time and can be conducted by two inspectors.

- Efficient inspection is possible because flaws in the longitudinal direction (L) and in the circumferential direction (T) can be detected at the same time with composite magnetization.

Flaw detection process image

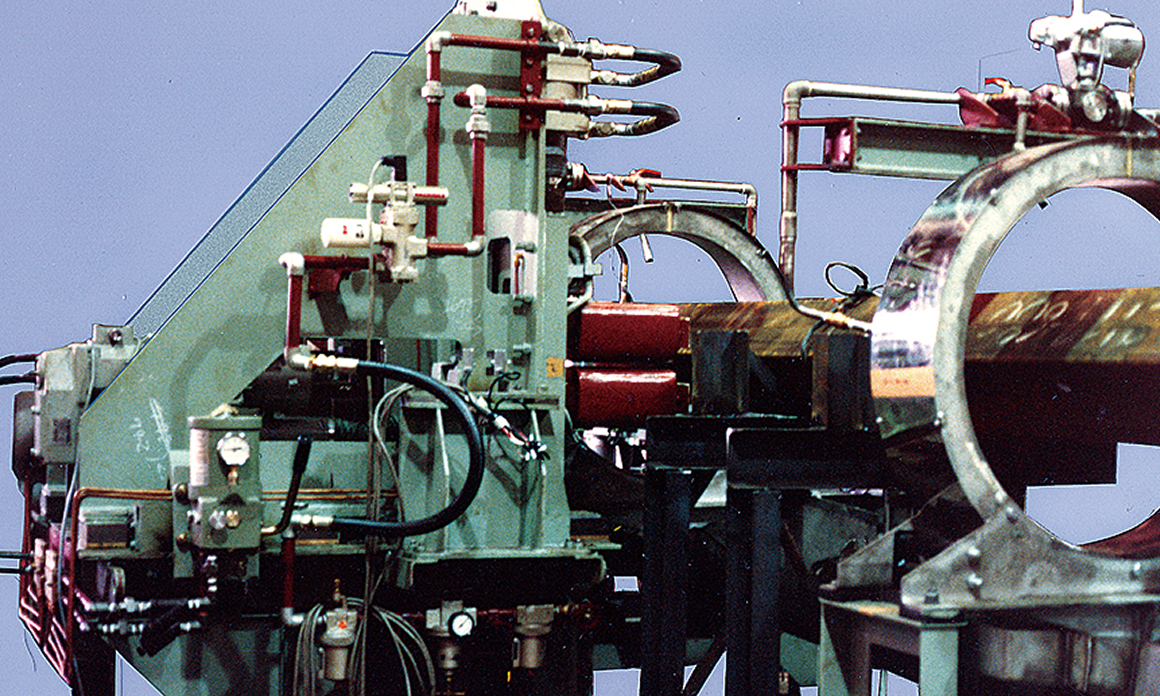

Billet Grinder Magna BGM

Features

- This device is used by combining the magnetic particle equipment and the flaw removing device (grinder).

- It is the device to detect defects in the longitudinal direction (L) by magnetizing them with the inter-polar coil in a traveling and contactless manner.It is possible to detect defects in the longitudinal direction (L) and in the circumferential direction (T) by combining with the encircling coil, and it is effective especially for detection of scabs on the corner part, etc.

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30

Other Magnetic particle testing Products

- Fluorescent magnetic particle

- Nonf luorescent magnetic particle

- Water-soluble magnetic dispersant

- Magnetic particle dispersing oil

- Water-soluble anti-rusting agent

- Water-soluble defoaming agent

Super Magna

The standard for magnetic particle inspection. We have a lineup of various types of products and can offer the best solution for your application.

- Fluorescent magnetic particle concentrated solution

- Dispersant

Eco Magna

Friendly to living things and the environment. The magnetic particle solution can be easily prepared. User-friendly fluorescent magnetic particle concentrated solution has appeared on the market.