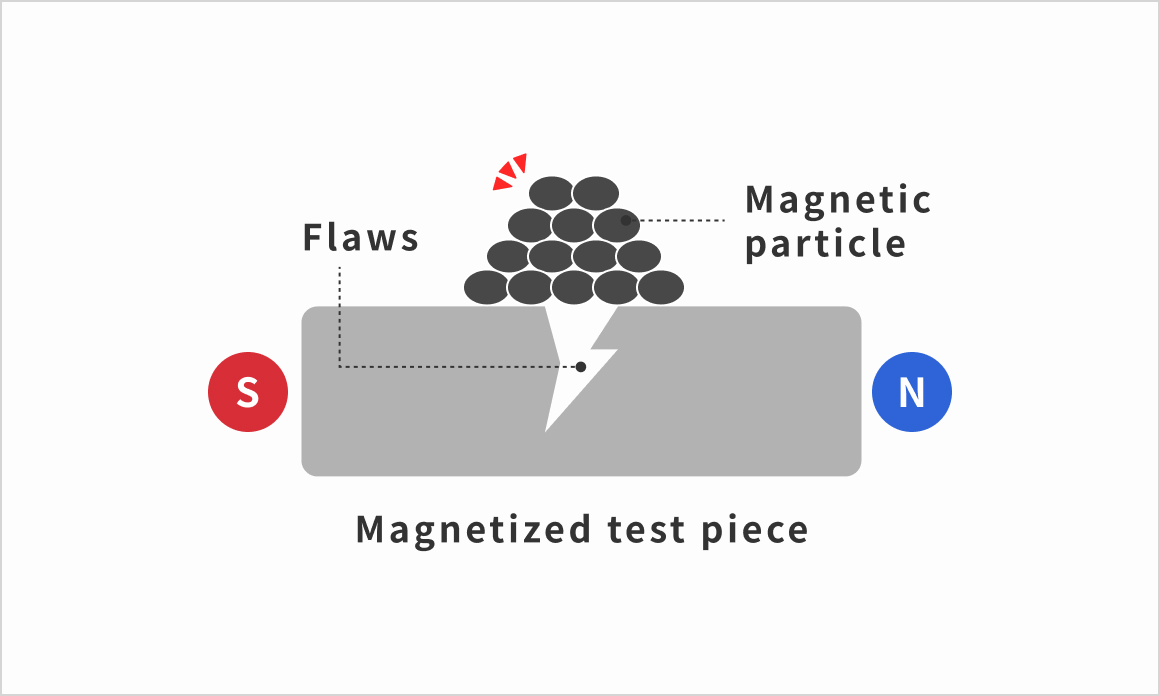

Test method

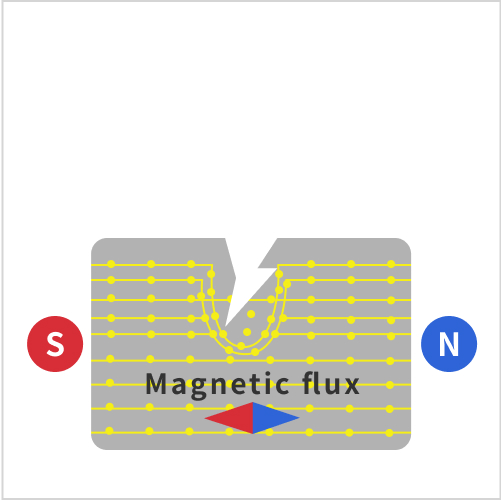

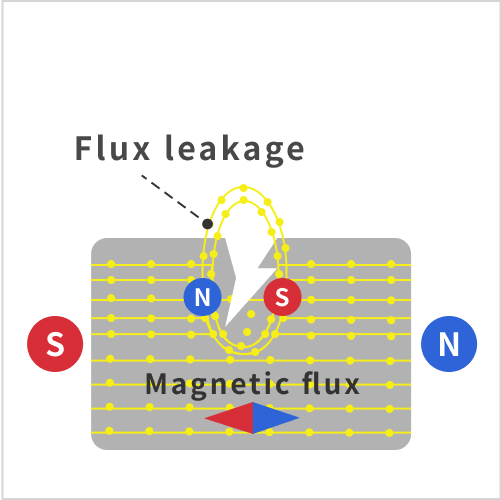

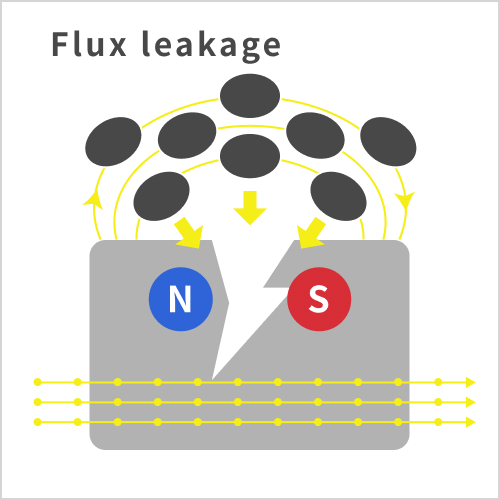

Magnetic particle testing is a method to confirm presence of flaws on or near the surface by magnetizing the test specimen.

It is the inspection most suitable for ferromagnetic materials such as iron, and it is possible to detect flaws in a short time.

Materials covered in the testing

- Ferromagnetic materials

Products used

- Flaw detection material

- Magnetizer

- Black light

Features of testing

feature

Testing method applicable to ferromagnetic materials such as iron

feature

It is possible to confirm inspection results immediately by magnetizing the test specimen and applying the inspection liquid

feature

It is necessary to choose the magnetizing method according to shape of test specimen, direction of flaw, etc.

Flow of flaw detection

Magnetic particle inspection tests are generally conducted using the following procedure.

①Pretreatment

②Magnetization※

③Generation of flux leakage

④Application of magnetic powders

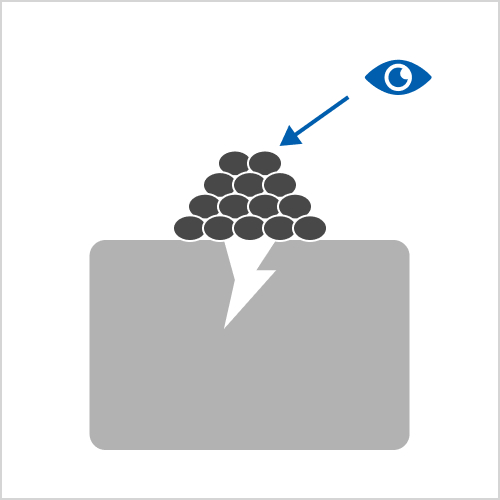

⑤Examination

※Generally, magnetization is performed using a magnetic particle detector or a hand magnetizer.

Flaw detection material lineup

Products used in magnetic particle testing can be selected from the following three types according to application and material.

Fluorescent magnetic particle concentrated solution type

Concentrated magnetic particle liquid type in which magnetic powder, dispersant, corrosion inhibitor, antifoaming agent, etc. are blended.

It is possible to prepare the inspection liquid only by pouring it into water.

Powder type

Standard type to be prepared by measuring magnetic powder and dispersant.

Corrosion inhibitor and antifoaming agent are poured if necessary.

Aerosol type

Aerosol type with no change in magnetic powder concentration filled with prepared magnetic powder solution. Ideal for outdoor testing of large castings and welded structures.

Fluorescent magnetic particle concentrated solution type Product List

Name | Fluorescent color | Particle size (μm) *2 | Compliant standard *1 | Usage |

|---|---|---|---|---|

Eco Magna LY-10 Conc. | Greenish yellow | 10 to 15 | AMS3044 SAE AS4792 | Exclusively for water dispersion, general-purpose product |

Eco Magna LY-20 Conc. | Greenish yellow | 12 to 20 | Exclusively for water dispersion, high brightness, for precision testing of steel material | |

Eco Magna LY-30 Conc. | Greenish yellow | 4.5 to 6.5 | Exclusively for water dispersion, for ultraprecision testing, polished round bar, etc. | |

Eco Magna LY-40 Conc. | Greenish yellow | 8 to 15 | Exclusively for water dispersion, general-purpose product |

*1 Meets applicable requirements for : AMS3044, SAE AS4792, ASTM E1444/E1444M, ASTM E709

*2 Particle size: Laser diffraction/scattering type (Volume standard)

Powder type lineup

Fluorescent magnetic particle/Nonf luorescent magnetic particle

Name | Fluorescent factor (cd/W) *1 | Particle size (μm) *2 | Compliant standard *3 | Usage |

|---|---|---|---|---|

Super Magna LY-10 | 7.6±10% | 10 to 15 | AMS3044 | Exclusively for water dispersion, general-purpose product |

Super Magna LY-20 | 10.1±10% | 12 to 20 | Exclusively for water dispersion, high brightness, for precision testing of steel material | |

Super Magna LY-30 | 4.9±10% | 4.5 to 6.5 | Exclusively for water dispersion, for ultraprecision testing, aircraft, polished round bar, etc. | |

Super Magna LY-40 |

| 8 to 15 | Exclusively for water dispersion, general-purpose product | |

Super Magna LY-50 | 4.7±10% | 10 to 15 | Exclusively for oil dispersion, general-purpose product | |

Super Magna WD-55 | – | – | AMS3040 | Dry type, general-purpose product |

Super Magna WD-104 | – | – | – | Dry type, general-purpose product |

Super Magna BW-334 | – | – | – | Wet type, general-purpose product |

*1 Evaluation by fluorescent factor (cd/W) Fluorescent factor = Brightness/UV intensity

*2 Particle size (μm): Laser diffraction/scattering type (Volume standard)

*3 Meets applicable requirements for : AMS3044, ASTM E1444/E1444M, ASTM E709

Magnetic dispersant, anti-rust agent, defoaming agent

Name | Recommended density | Feature |

|---|---|---|

Super Magna BC-1S | 0.1 to 0.2% | Adding even a small amount effectively provides dispersibility and defoaming ability to the magnetic particle solution. |

Super Magna BC-700 | 11.0 to 2.0% | Ideally, apply after flaw detection. |

Eco Magna EC-4 | 0.5% | Friendly to humans and the environment, with superior dispersibility/wettability for magnetic particles. Compatible with AMS3044. |

Super Magna SO-220B | – | High flashing point, low odor, no fluorescence Suitable for inspecting smooth surfaces with high viscosity. Compatible with AMS2641. |

Super Magna SO-220C | – | High flashing point, low odor, no fluorescence Suitable for rough surfaces with low viscosity. Compatible with AMS2641. |

Super Keep AR-100K | 1.0 to 5.0% | Add a temporary anti-rusting property to the magnetic particle solution. |

Super Magna 71A | 0.1 to 0.2% | Control foaming in the magnetic particle solution. |

Aerosol type

Oil based

No concerns about rust on the test piece. The dispersing agent has low toxicity and no odor, ensuring a comfortable test environment.

Quick-drying

The magnetic particle solution dries immediately after being applied, which facilitates transfer of the flaw indication. Due to its quick-drying property, the liquid will not dribble even when sprayed upwards.

Water based

Purified water is used as the dispersing agent, so foul odors are not generated. The Fire Defense Law does not apply to the dispersing agent and safety is improved.

| Oil based | Quick-drying | Water based | |

|---|---|---|---|

| Charged gas | LPG | LPG | DME/CO2 |

| Main dispersing agent/flashing point (undiluted solution) | Hydrocarbon solvent/95°C | Hydrocarbon solvent/-4°C | Purified water, nonhazardous substance*2 |

| Magnetic particle density | 2.0g/L | 1.5g/L | 0.75g/L |

| Quantity contained | 290g | 280g | 420g |

| Fluorescent factor (cd/W) *1 | 4.7±10% | 4.7±10% | 7.6±10% |

| Particle size | By laser diffraction scattering type measurement (Volume standard) 10 to 15μm | ||

*1: Evaluation by fluorescent factor (cd/W) Fluorescent factor = Brightness/UV intensity

*2: Though the undiluted solution is nonhazardous, this product is regarded as a hazardous substance during transportation because it is an aerosol.

How to use each product

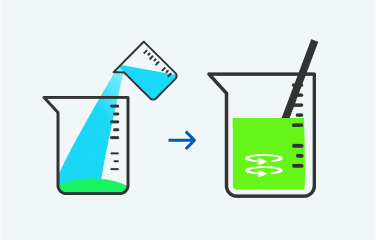

How to use Fluorescent magnetic particle concentrated solution type (how to make magnetic powder solution)

- STEP

Add 500mL of magnetic particle concentration to 100L of water.

- STEP

By stirring, a uniform magnetic particle solution (density: 1.0g/L) can be prepared.

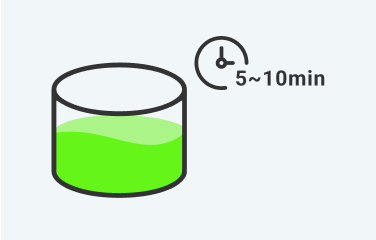

- STEP

After 5 to 10 minutes, confirm suspension of the magnetic particle solution, and start testing.

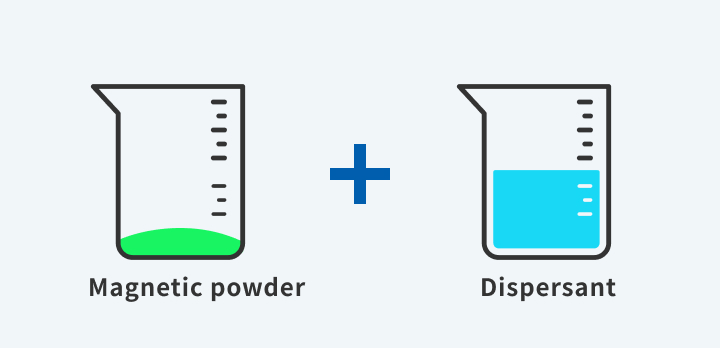

How to use the Powder type (how to make magnetic powder solution)

- STEP

Calculate the necessary amount of magnetic particles and dispersant, weigh them, and place in containers.

- STEP

Slowly add the dispersant into the magnetic particles, and knead well to form a paste.

- STEP

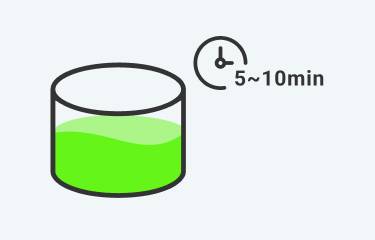

Add the magnetic particle paste into the tank and stir it.

- STEP

After 5 to 10 minutes, confirm suspension of the magnetic particle solution, and start testing.

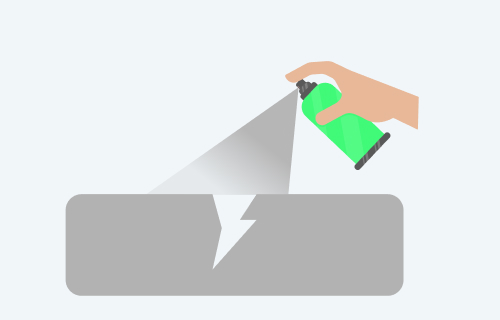

How to use Aerosol type

- STEP

Shake the aerosol well before use to agitate the magnetic powder liquid in the container.

- STEP

Spray the area to be probed and start the inspection.

Details of product

- Fluorescent magnetic particle

- Nonf luorescent magnetic particle

- Water-soluble magnetic dispersant

- Magnetic particle dispersing oil

- Water-soluble anti-rusting agent

- Water-soluble defoaming agent

Super Magna

The standard for magnetic particle inspection. We have a lineup of various types of products and can offer the best solution for your application.

- Fluorescent magnetic particle concentrated solution

- Dispersant

Eco Magna

Friendly to living things and the environment. The magnetic particle solution can be easily prepared. User-friendly fluorescent magnetic particle concentrated solution has appeared on the market.

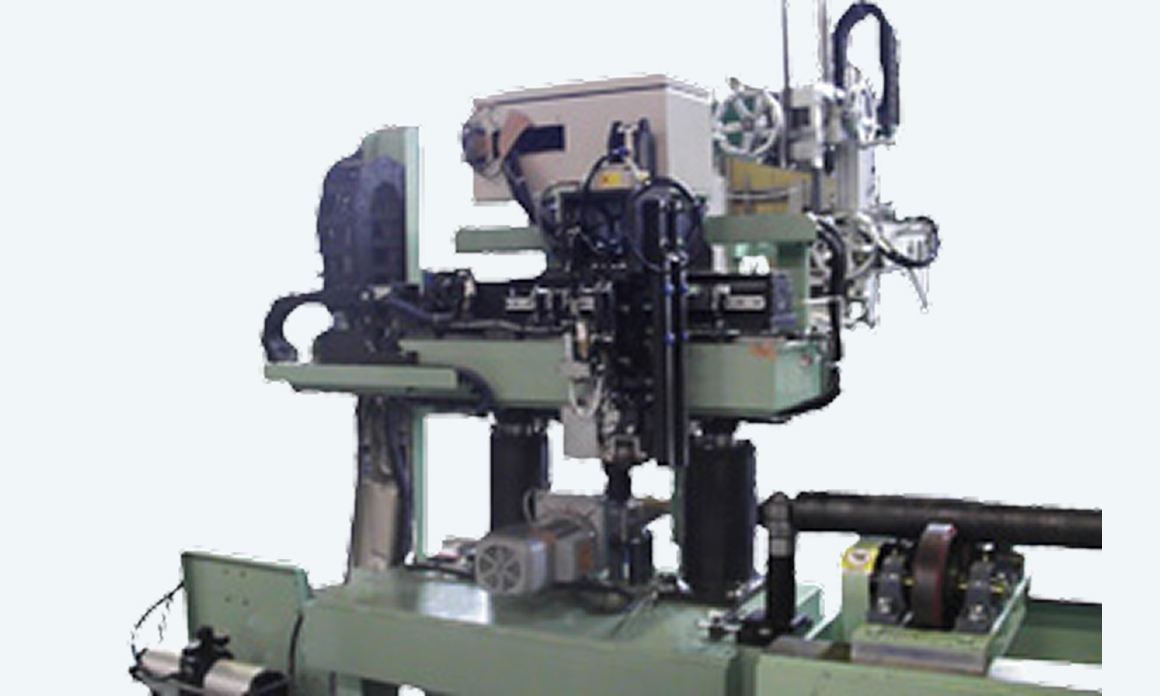

Magnetic particle equipment

Introduction of magnetic particle equipment is common in the case of mass inspection of mass produced items, etc. MARKTEC can propose magnetic particle equipment, including feeding, for castings and forgings of ferromagnetic materials (iron, etc.) and billets manufactured by steel manufacturers.

Related products

Black light・UV intensity tester

MARKTEC’s black lights (ultraviolet flaw detection lights) are designed and fabricated under the most suitable conditions for flaw detection testings in which ultraviolet rays (UV-A) including 365 nm are irradiated.

Tesla meter

MARKTEC provides tesla meters (analogue-type, digital-type) to measure the magnetic flux density of the objects.

Magnetic particle liquid evaluation equipment

Sedimentation meters used for management of inspection liquid have issues such as being unable to distinguish magnetic powders and scales, being unable to evaluate the deterioration of inspection liquid contaminated with oil, etc. Towards such issues, MARKTEC developed the magnetic particle liquid evaluation equipment to enable management of inspection liquid by quantifying it as “detection level”. We can offer a trial, so please feel free to contact us.

Sedimentation meter

If the inspection liquid is poured into the tank of the magnetic particle equipment and continuously used, the magnetic powders are taken away by the test specimen and the concentration of magnetic powder is lowered. The sedimentation meter is used for measuring the concentration of magnetic powder from the amount of deposited magnetic powder, by sampling the inspection liquid in the tank with the sedimentation meter and leaving it for a certain period of time.

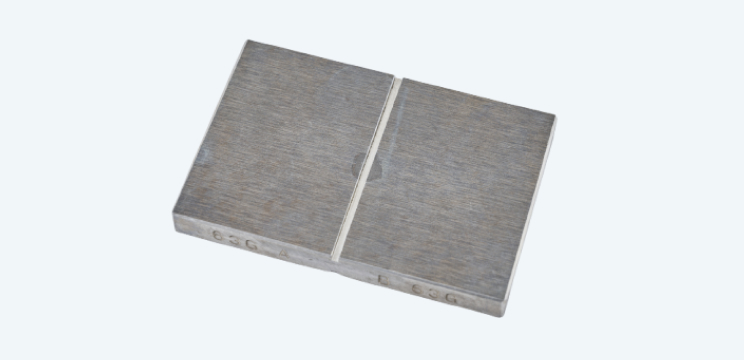

Test pieces for magnetic particle testing (link destination)

They are used for checking the strength and direction of the magnetic field on the testing surface, performance inspection of flaw detection equipment and inspection liquid, checking the effective range of flaw detection and conditions of flaw detection, etc.

Hand-Magna

A portable magnetizer of inter-polar type is generally called “Hand Magna”. It is often used for outdoor inspections, large test specimen, etc. It is possible to conduct flaw detection on corner parts other than flat planes by attaching a yoke. It is the magnetizer easy to introduce as it is less expensive than the stationary flaw detection equipment.

Product Column

Well-understood course

A Course to Better Understand Magnetic Particle Testing

About designated quantities

in the Fire Service Law

Non-destructive testing・Printing and marking

About designated quantities in the Fire Service Law

Preparation of inspection liquid

Non-destructive testing・Printing and marking

Preparation of inspection liquid (magnetic particle liquid)

Non-destructive testing・Printing and marking

Test pieces for magneticparticle testing

Non-destructive testing・Printing and marking

How to apply magnetic particles to test objects

Product information for

Magnetic Particle Testing Materials

can also be found in the catalog.

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30