Test method

For leakage inspections, there are various kinds such as oil leakage, water leakage, air leakage, etc.

MARKTEC can propose the leakage inspection materials suitable for applications.

Oil leakage test

Super Tracer OL-200 II [Ultra high concentration]・Super Tracer FT-32 / FT-56・Leak Check WB-A

Water leakage test

Super Glo DF-300 Liquid

Air leakage test

Super Bubble TR-1/TR-1C

Product lineup and how to use

You can choose from the following three applications for leak inspection and bubble leak inspection products.

Oil leakage test

Air leakage test

Water leakage test

Super Tracer OL-200 II [Ultra high concentration]

Features

- Fluorescent leakage inspection material to be oil-diluted for use

- It can be handled easily and detect even a small amount of leakage without failure

- Small impact on operating machinery and packings

- It helps you to manage hydraulic equipment appropriately

use

- Hydraulic equipment

- large tanks

- piping

How to use

STEP

With hydraulic oil used for hydraulic equipment or another suitable liquid, dilute 0L-200 II to 0.1% to 0.2% and stir the liquid.

STEP

Operate the machine and circulate the mixed oil through the entire machine.

STEP

Irradiate ultraviolet rays to the target under an ultraviolet flaw detection light (black light), and follow the circulation route.

Since leakage spots, if any, emit fluorescence, you can find even a minute amount of leakage easily.

MARKTEC’s Super Light D-10L is available and is convenient as the ultraviolet flaw detection light.

Super Tracer FT-32 / FT-56

Features

- Fluorescent leakage inspection material to be oil-diluted for use

- Small viscosity-change of the turbine oil

- The FT-32 type matches the viscosity of ISO VG 32 turbine oil

- The FT-56 is a type matching the viscosity of turbine oil equivalent to the previous ISO VG56

Use

- Hydraulic equipment

- large tanks

- Piping

How to use

STEP

With hydraulic oil used for hydraulic equipment or another suitable liquid, dilute FT-32/FT-56 to 3% to 5% and stir the liquid.

STEP

Operate the machine and circulate the mixed oil through the entire machine.

STEP

Irradiate ultraviolet rays to the target under an ultraviolet flaw detection light (black light), and follow the leakage spots.

※MARKTEC’s Super Light D-10L is available and is convenient as the ultraviolet flaw detection light.

Ultraviolet flaw detection light (black light)

Super Light D-10L

- LED adopted; it can be lit up instantly.

- High intensity in a wide range

Intensity in the center 4,050 μW/cm2 (Irradiation distance 318 mm) - Peak wavelength: 365 nm (JIS-compliant)

Battery type LED black light UV-9L

- LED adopted; it can be lit up instantly.

- Compact and lightest in weight 70 g (dimensions Φ31 × 98 mm)

- With 3 AAA batteries, it can continue to light up for 5 hours

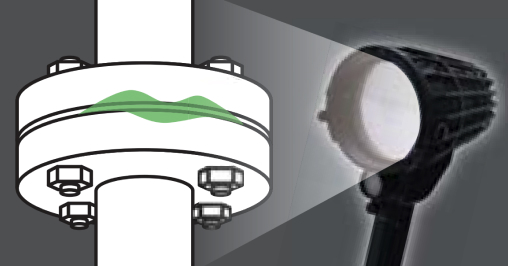

Concept of inspection(Super Tracer OL-200Ⅱ/FT-32 / FT-56 Super Glo DF-300 Liquid)

* The fluorescent color emitted varies depending on the product.

Leak Check WB-A

Features

- Because of the fine powder particles, it has a clear coating film and a good contrast with the part of oil leakage

- Because of its high removal performance, it can be removed just by being wiped lightly or by blowing air on it after completion of inspection

- Because of quick drying of the solvent, it can be inspected efficiently even in winter or in a highly humid environment

- Low corrosiveness to metals

- Aerosol: The coated area is approx. 3.5 m2 per can

Use

- Power steering

- Gearbox casing

- transmission

- Clutch casing

- Engine

- Hydraulic unit

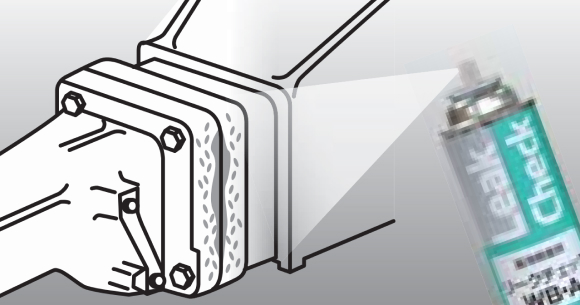

How to use

STEP

With a dry shop cloth or similar cloth, wipe off the target area of inspection thoroughly so that any foreign matter is removed.

STEP

Spray WB-A uniformly to the target area, and leave it for 5 minutes or more.

STEP

When the oil comes out, only the color in that part changes. (When the amount of oil leakage is little, please leave it for a long time.)

STEP

After inspection, wipe it lightly with a dry shop cloth or blow it off with air of 0.6 MPa or more to remove the powder.

Concept of inspection

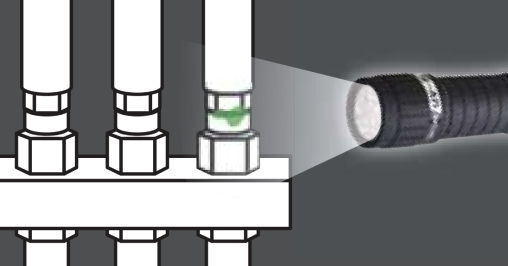

Super Bubble TR-1/TR-1C

Features

- Good bubbling and suitable de-foaming ability

- Because it has moderate viscosity, it is OK even on an inclined plane

- Based on JIS-Z-2329 Methods for Bubble Leak Testing, using the foaming test piece BL30, foaming was confirmed at a pressure of 4 x 103 Pa.

- No adverse effects such as corrosion on test specimens * Low sulfur and low halogen (S: ≤ 10 ppm; Cl: ≤ 100 ppm; F: ≤ 30)

use

- Gas piping

- Compressors

- Valves

- Welds

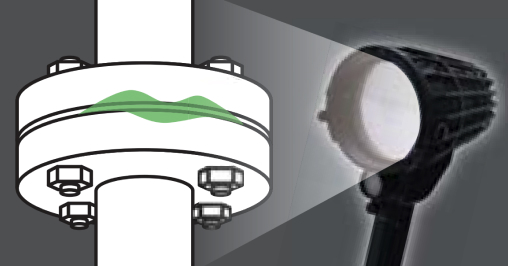

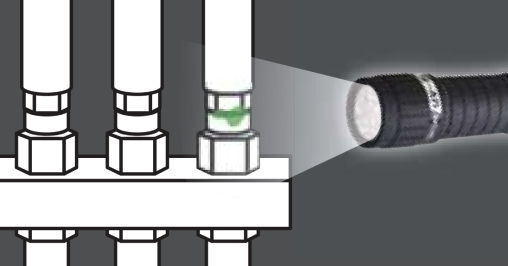

How to use

STEP

Apply TR-1 to the test area.

* For TR-1C (undiluted solution), dilute it 10 times with water before use.

STEP

Pressurize or depressurize the container. With bubbles, you can find leakage easily.

Inspection image

Super Glo DF-300 Liquid

Features

- Water-soluble fluorescent leakage inspection material that is to be diluted with water for use

- Leakage spots can easily be located by irradiating ultraviolet rays to the target under an ultraviolet flaw detection light (black light)

- Because the Fire Services Act does not apply to this product, there are no restrictions including the specified quantity

use

- Shower test of automobile body

- water leakage test of tanks

- leak test of condenser tube

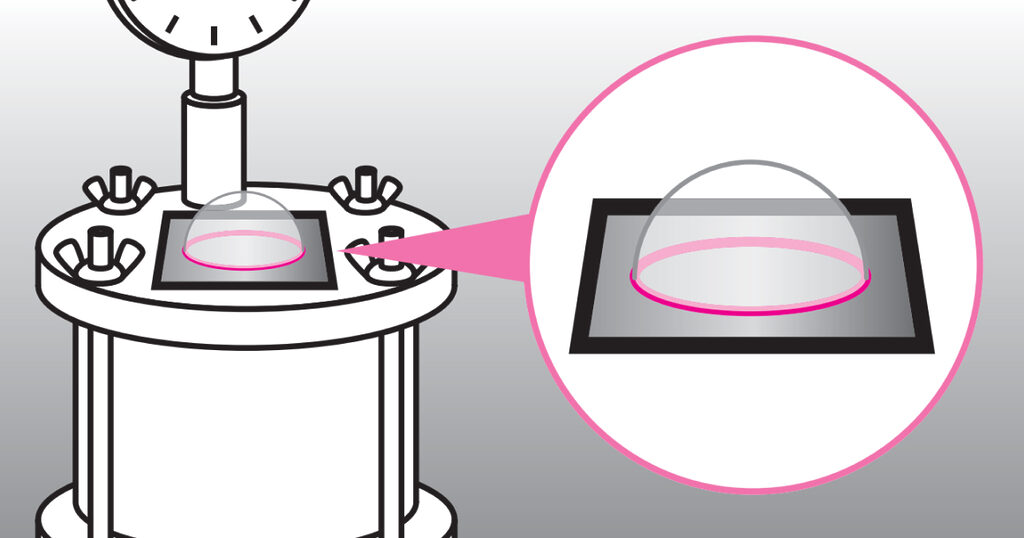

How to use

STEP

With water, dilute DF-300 Liquid to 0.005% to 0.1% and stir the liquid.

STEP

Place the diluted water-soluble liquid in the test piece and leave it as it is.

※ Exposure time depends on the size of the penetration point.

※Pressurizing the test piece can shorten the inspection time if it can be pressurized.

STEP

By irradiating the target under an ultraviolet flaw detection light (black light) from the outside, the leakage spots emit a fluorescent color, leading to easier detection.

※In a shower test of the automobile body, when sprayed on an automobile body and irradiated with ultraviolet rays from the inside with ultraviolet flaw detection light (black light), the leakage part emits a fluorescent color, so even a minute leak can be easily found.

Ultraviolet flaw detection light (black light)

Super Light D-10L

- LED adopted; it can be lit up instantly.

- High intensity in a wide range

Intensity in the center 4,050 μW/cm2 (Irradiation distance 318 mm) - Peak wavelength: 365 nm (JIS-compliant)

Battery type LED black light UV-9L

- LED adopted; it can be lit up instantly.

- Compact and lightest in weight 70 g (dimensions Φ31 × 98 mm)

- With 3 AAA batteries, it can continue to light up for 5 hours

Concept of inspection(Super Tracer OL-200Ⅱ/FT-32 / FT-56 Super Glo DF-300 Liquid)

* The fluorescent color emitted varies depending on the product.

Product Column

About designated quantities

in the Fire Service Law

Non-destructive testing・Printing and marking

About designated quantities in the Fire Service Law

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30