Product Description

Introduction of fluorescent penetrant equipment is common in the case of mass inspection of mass produced items, etc.Here are examples of the proposals by MARKTEC.

Details of product

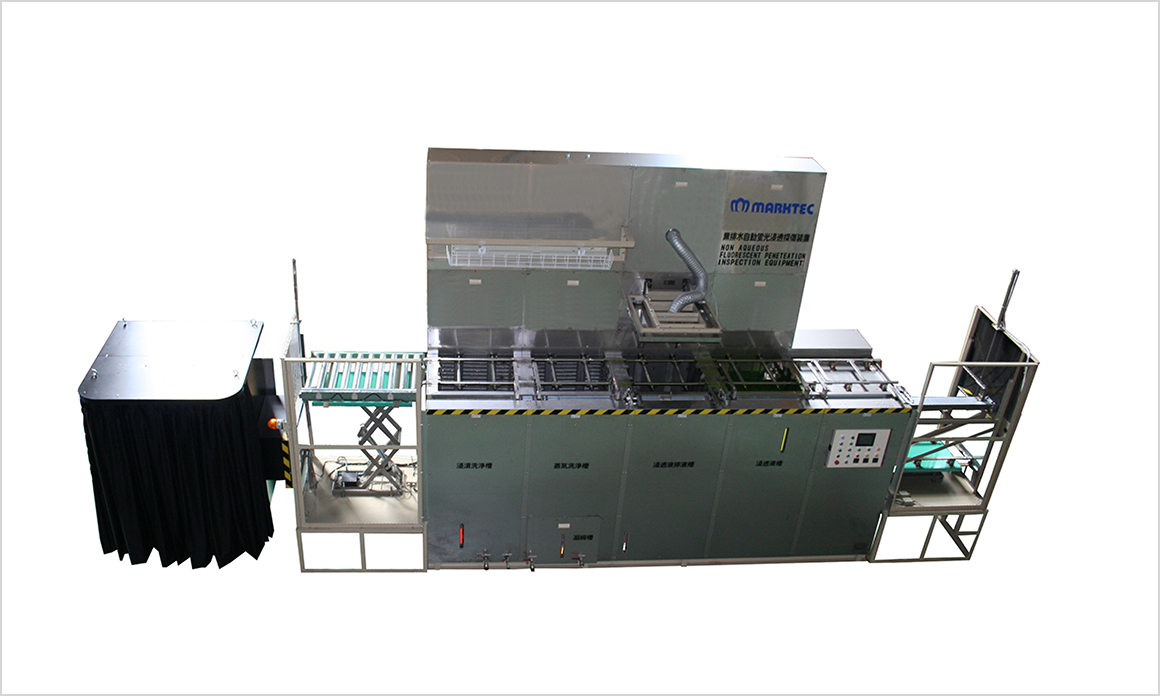

Washable fluorescent penetrant equipment MA-type

Features

- Equipment corresponding to methods A, B, and D types required in relation to aircraft.

- Also supporting the non-development method in which development processing is not conducted.

- It is possible to choose from three kinds of standard equipment depending on the size of the inspection object.

- It is possible to design and fabricate the equipment with special specification to meet the customer’s application, etc.

- Designs conforming to ASTM E1417 are possible.

Introduction examples

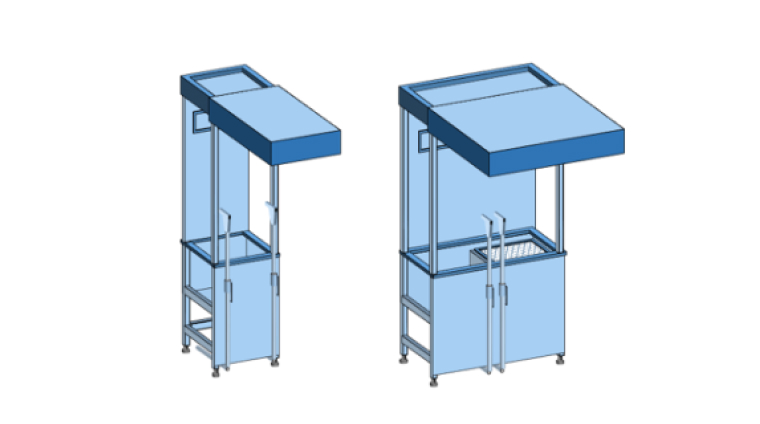

- Washable fluorescent penetrant equipment MA-1

- Booth-type fluorescent penetrant equipment

Composition

Penetrant tank/draining stand

Conduct penetration processing by soaking the test specimen into the tank.

After penetration processing, move the test specimen to the draining stand and take time for penetration while draining the liquid.

The drained penetrant is recovered to the penetrant tank.

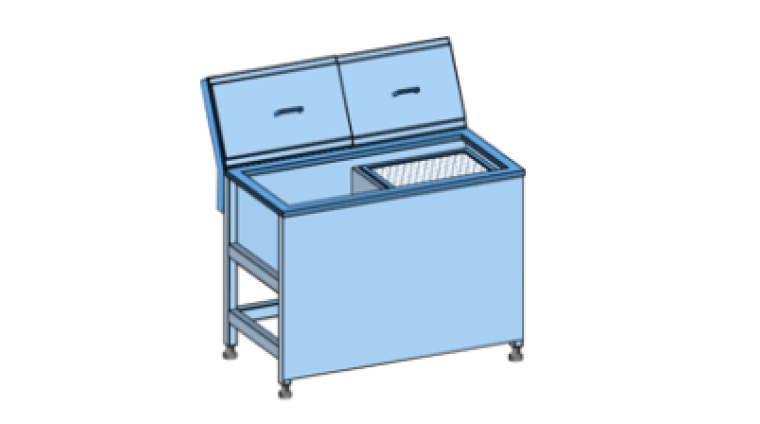

Preliminary cleaning/main cleaning tank

Conduct cleaning processing for excess penetrant by spraying water to the test specimen for which penetration processing has been conducted.Setting temperature and pressure is possible as the heating and pressurizing device is equipped.

Emulsification tank

Conduct emulsification processing by soaking the test specimen into the tank.

After emulsification processing, move the test specimen to the draining stand and take time for emulsification while draining the liquid

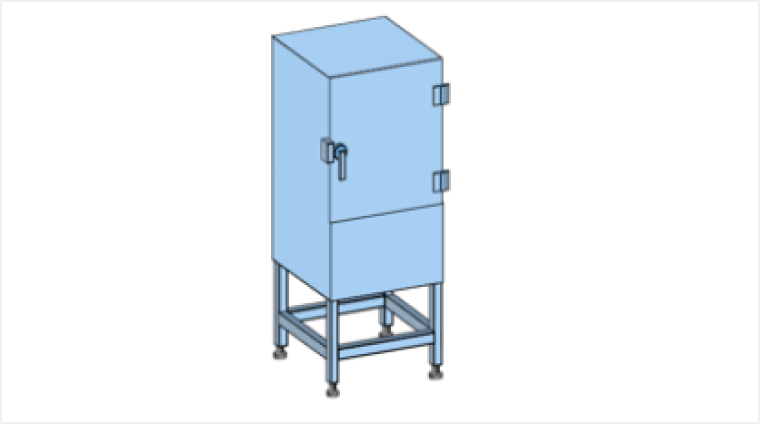

Drying device

After cleaning processing, dry water which remains on the surface of the test specimen.

Control temperature with the heater-method.

Dry-method development device

Conduct development processing by jetting the developing powder into the processing chamber with the air-flying method.

Inspection room

Observe flaws by using black lights in the inspection room.

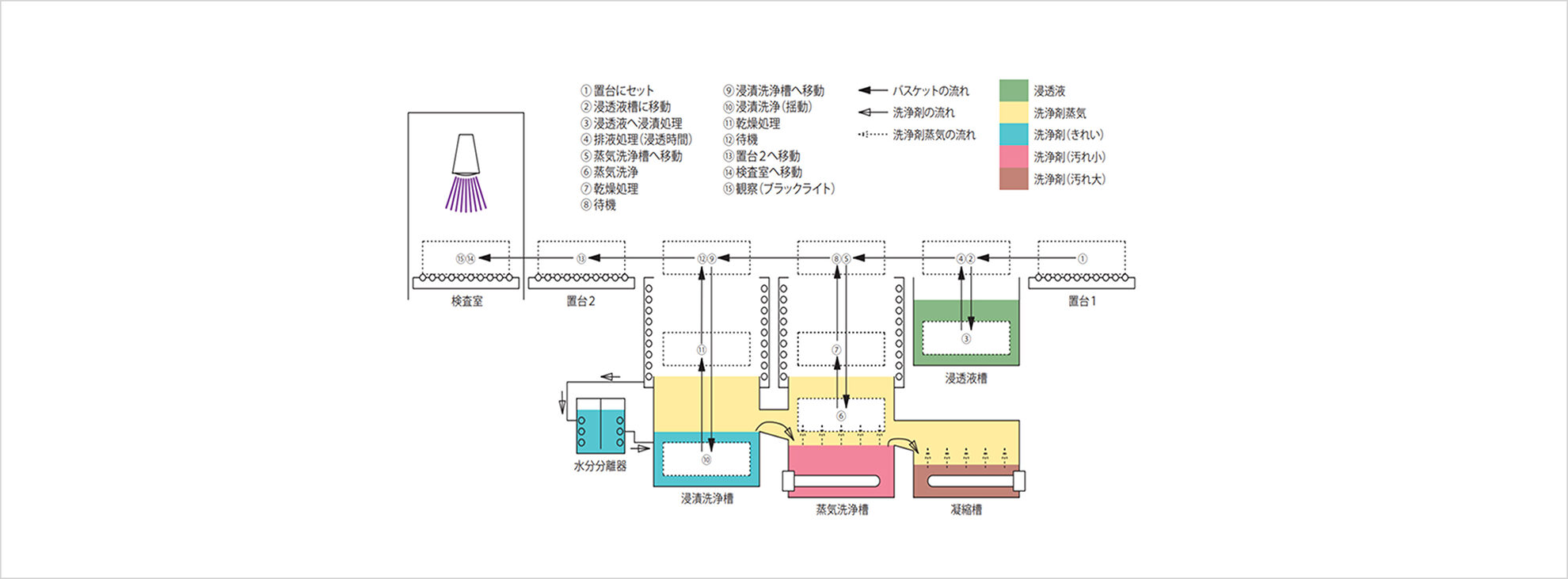

Non-draining fluorescent penetrant equipment MH-1

Features

- Wastewater treatment equipment is not required as no water is used for cleaning.

- The solvent dedicated to this equipment is cooled and recovered to be reused for cleaning.

- No drying device is required as the dedicated solvent with quick-drying property is used.

- Processing time is significantly improved as the drying time, which was previously the time consuming part of the process, is shortened.

- No post-processing after flaw detection is required because of the non-development method.

Composition

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30

Other Fluorescent penetrant testing (general) Products

- Cleaner/Remover

- Developer

- Fluorescent penetrant

Super Glo

Super-Glo is standard fluorescent penetrant flaw detection material. The rich and varied lineup provides penetrants that are optimal for a wide range of applications and purposes.

- Fluorescent penetrant

Eco Glo

Eco-Glo is an ecological penetrant with main components that are safe for people and the environment. It maintains all the penetrating performance of standard penetrant while also providing improved wastewater treatment and washing performance.