Test method

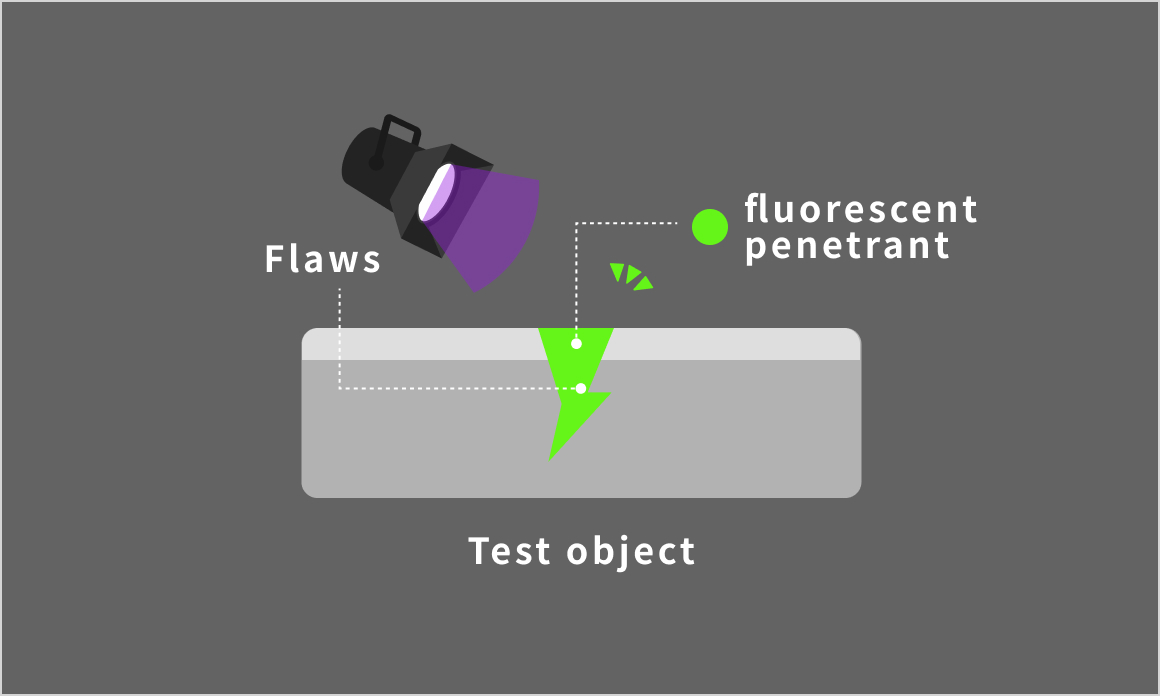

Fluorescent penetrant testing is a method to find fine flaws opened on the surface of the test specimen by impregnating a shimmery liquid into them to enlarge the flaw.It is used when mass inspection of mass produced items, etc. is required.

*For those who are considering the fluorescent penetrant testing in the aircraft industry, please see here.

View test methods for Fluorescent penetrant testing (for the aircraft industry)

Materials covered in the testing

- Metallic and non-metallic material

Products used

- Flaw detection material

- Black light

- Flaw detection equipment (In case of many inspections)

Features of testing

feature

Flaw detection is possible even for metallic and non-metallic materials if they are not affected by flaw detection materials and have no hygroscopic property

feature

It is easy to apply even to complicated test specimens as flaw detection materials are liquid

feature

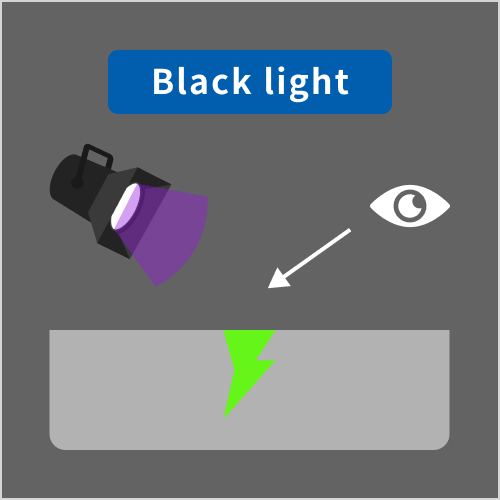

Indicated patterns (flaws) are observed by using the black light

feature

In many cases, it is adopted in conducting mass inspection by introducing the flaw detection equipment

feature

In the non-development method, post-processing (removal of developing agent) is not required

Flow of flaw detection

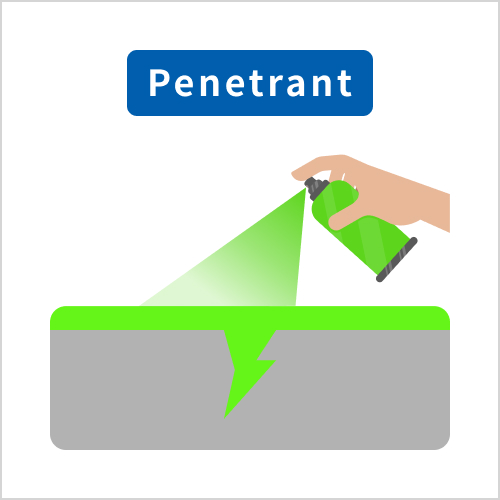

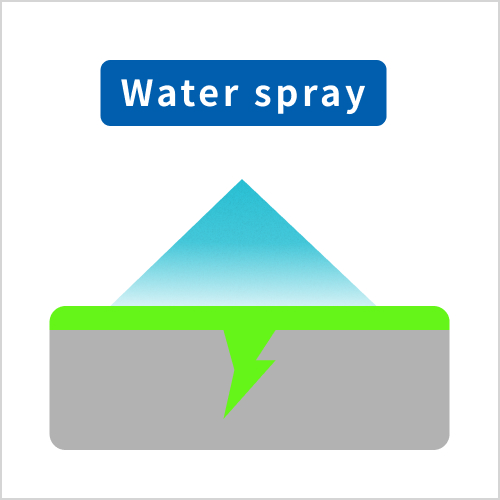

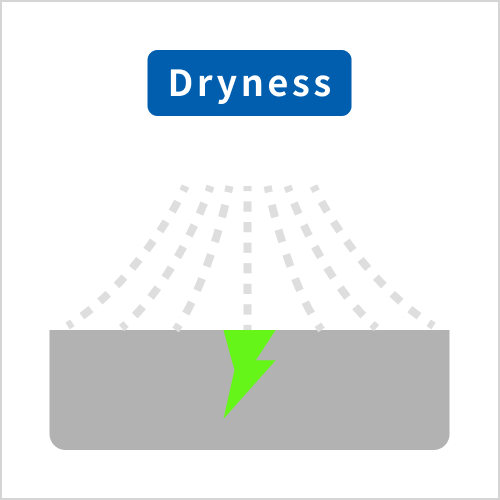

Fluorescent penetrant testing (non-development method) is generally conducted by the following procedure.

①Pretreatment

②Penetration treatment

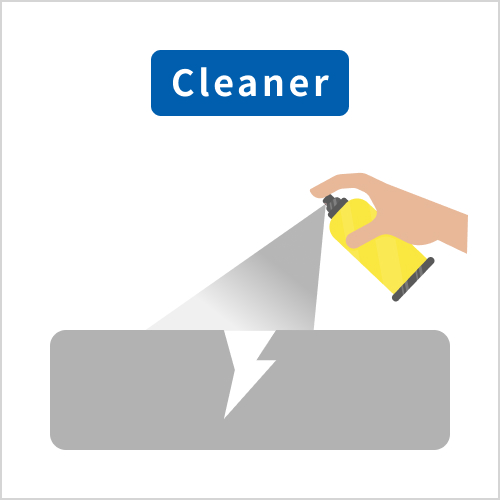

③Removal

④Drying treatment

⑤Examination

Flaw detection material lineup

| Category | Product Name | Compatible with JIS | Features |

|---|---|---|---|

| Penetrant | Super Glo OD-1800N | Excellent wastewater treatment and low foaming. | |

| Super Glo OD-2800N | High fluorescent brightness and high sensitivity. | ||

| Super Glo OD-2800Ⅱ | High fluorescent brightness and higher sensitivity than the OD-2800N. | ||

| Super Glo OD-2800Ⅲ | Extremely high fluorescent brightness and optimal for hairline crack detection. | ||

| Super Glo OD-2800T | Super high sensitivity type using specially refined materials (Sensitivity level 4). Optimal for flaw detection in nuclear power equipment. | ||

| Super Glo OD-2900Ⅲ | ✓ | High sensitivity type with less foaming than the OD-2800 III (Sensitivity level 3). | |

| Super Glo RP-2000C | ✓ | Solvent-removable fluorescent penetrant. Low viscosity makes it optimal for detecting penetration flaws. | |

| Super Glo OD-20S | Water-based fluorescent penetrant to eliminate fire hazard. | ||

| Super Glo OD-50A・Ⅱ | Water-based fluorescent penetrant with low COD value to eliminate fire hazard. | ||

| Eco Glo EG-2000 | Water-based fluorescent penetrant, no fire hazard. Low foaming when drained, low COD value. | ||

| Developer | Super Glo UD-T | ✓ | Quick-drying developer. Optimal for flaw detection in nuclear power equipment. |

| Super Glo DN-600P | ✓ | Dry developer. Fine white powder with excellent ultraviolet transmittance. Fluorescent glow of flaw indication allows users to detect minute flaws. | |

| Super Glo DN-905D | Wet developer. Uses fine powder scattered in a fixed amount of water. Shows excellent contrast and provides clear indication of flaws without blurring. | ||

| Super Glo DN-600S | Aerosol-type quick-drying developer. Quick drying provides increased penetrant suction force. | ||

| Remover | Super Glo AS-T | ✓ | Solvent remover for water washing (water spray). Optimal for flaw detection in nuclear power equipment. |

Details of product

- Cleaner/Remover

- Developer

- Fluorescent penetrant

Super Glo

Super-Glo is standard fluorescent penetrant flaw detection material. The rich and varied lineup provides penetrants that are optimal for a wide range of applications and purposes.

- Fluorescent penetrant

Eco Glo

Eco-Glo is an ecological penetrant with main components that are safe for people and the environment. It maintains all the penetrating performance of standard penetrant while also providing improved wastewater treatment and washing performance.

Fluorescent penetrant equipment

Related products

Black light・UV intensity tester

MARKTEC’s black lights (ultraviolet flaw detection lights) are designed and fabricated under the most suitable conditions for flaw detection testings in which ultraviolet rays (UV-A) including 365 nm are irradiated.

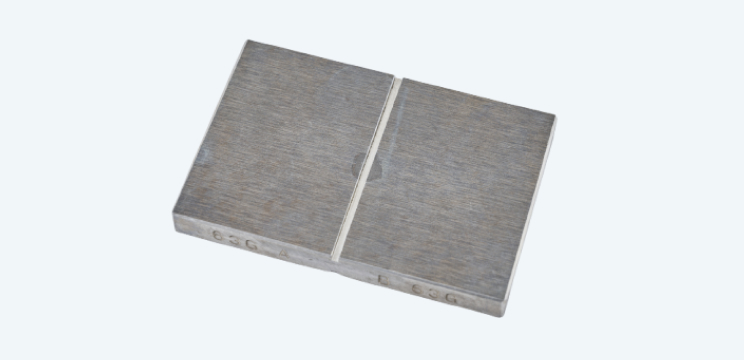

Test pieces for magnetic particle testing (link destination)

They are used for checking the strength and direction of the magnetic field on the testing surface, performance inspection of flaw detection equipment and inspection liquid, checking the effective range of flaw detection and conditions of flaw detection, etc.

Product Column

A Course to Better Understand Penetrant Testing

Well-understood course

A Course to Better Understand Penetrant Testing

About designated quantities

in the Fire Service Law

Non-destructive testing・Printing and marking

About designated quantities in the Fire Service Law

Non-destructive testing・Printing and marking

About treatment of wastewater after flaw detection testings

Product information for Fluorescent

Penetrant Flaw Detection Material

can also be found in the catalog.

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30