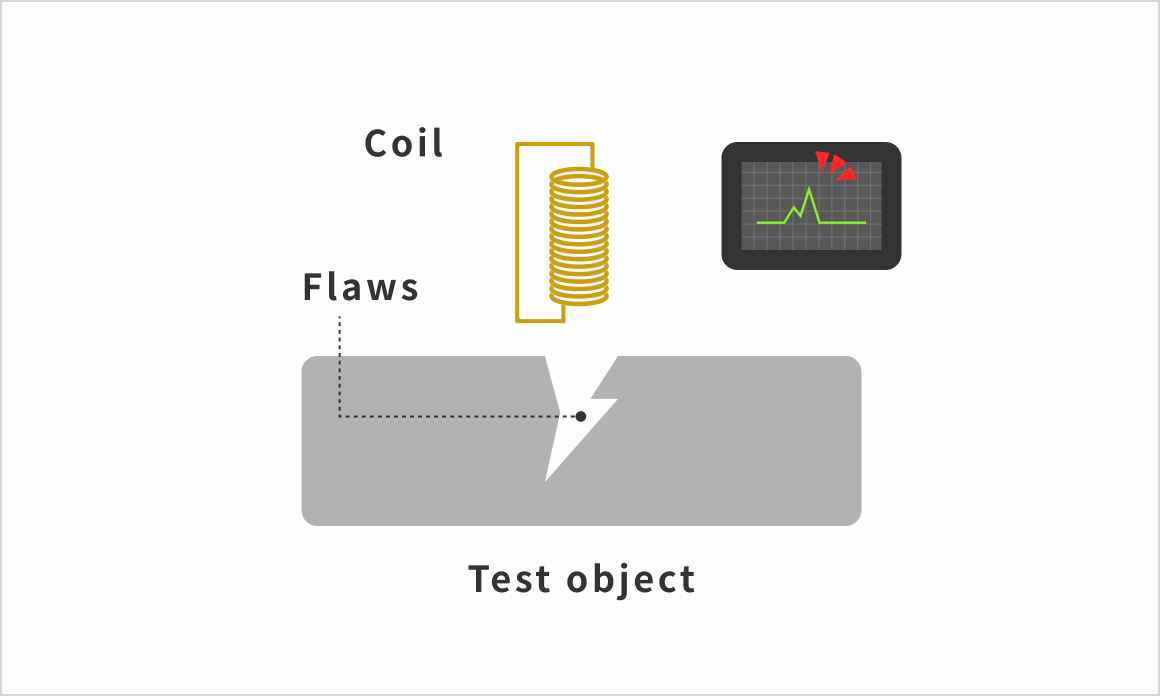

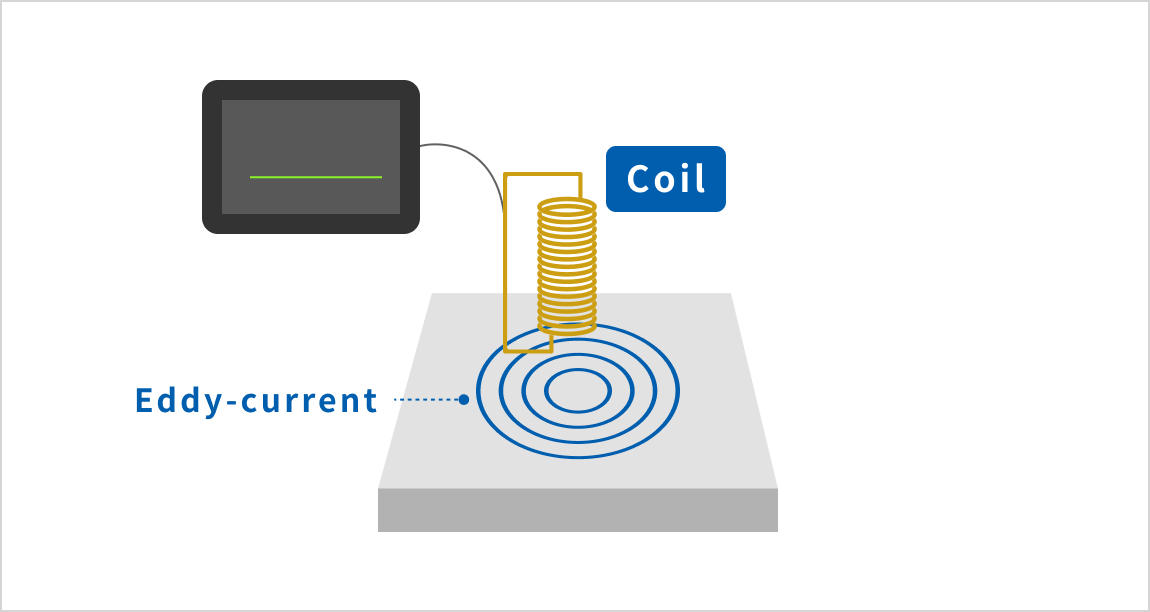

Test method

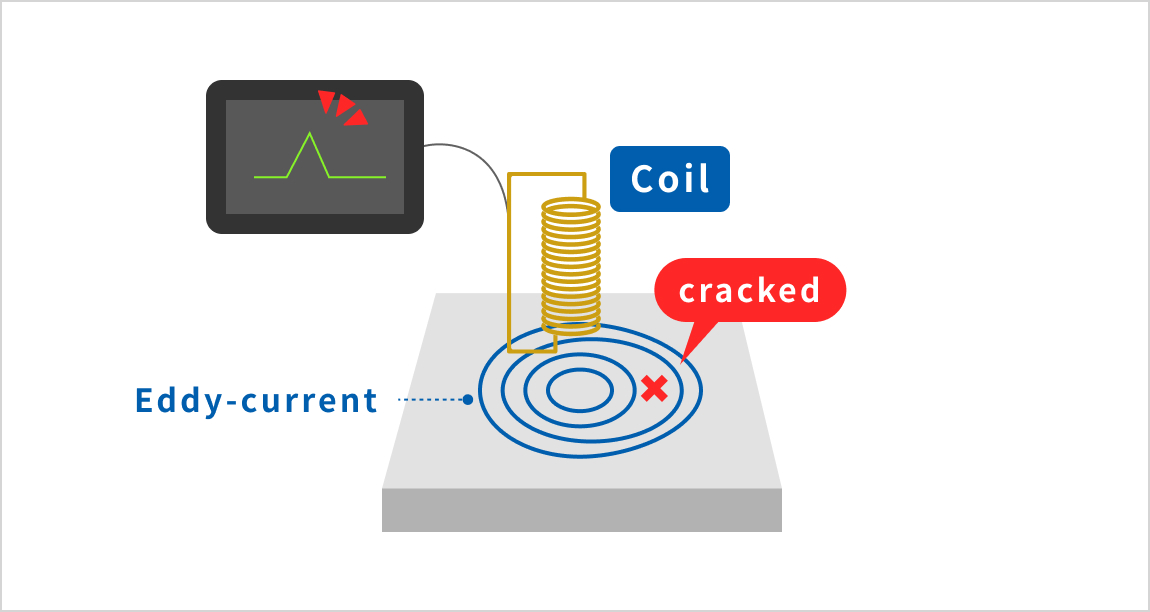

Eddy current testing is a method to confirm presence of flaws opened on the surface of the test specimen by utilizing the electromagnetic induction phenomenon using the coil.

It is possible to conduct automatic/mass inspections by introducing the eddy current flaw detection equipment.

Materials covered in the testing

- Conductive materials

Products used

- Eddy-current flaw detection equipment

Features of testing

feature

Testing method applicable to conductive materials.

feature

Most suitable for inspections for simple shapes

feature

It is possible to conduct flaw detection at high speed, without contacting the inspecting object

feature

It is easy to record/store flaw detection results as they are obtained by electric signals

Flow of flaw detection

Eddy current testing is generally conducted by the following procedure.

In case of no defects

In case of defects

Types of eddy current flaw detection

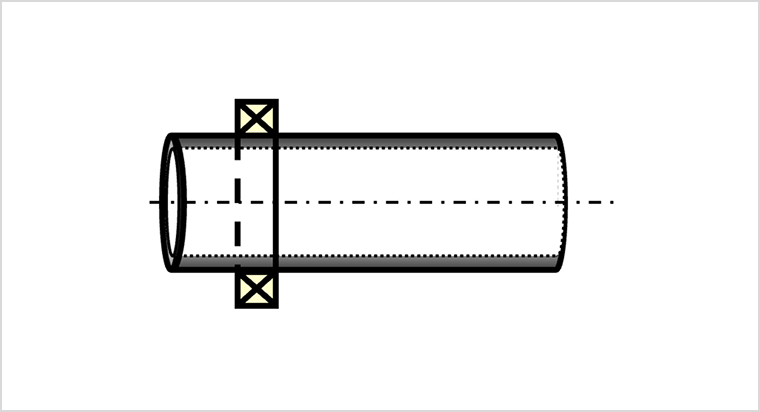

- Penetration ET

The test specimen penetrates the probe

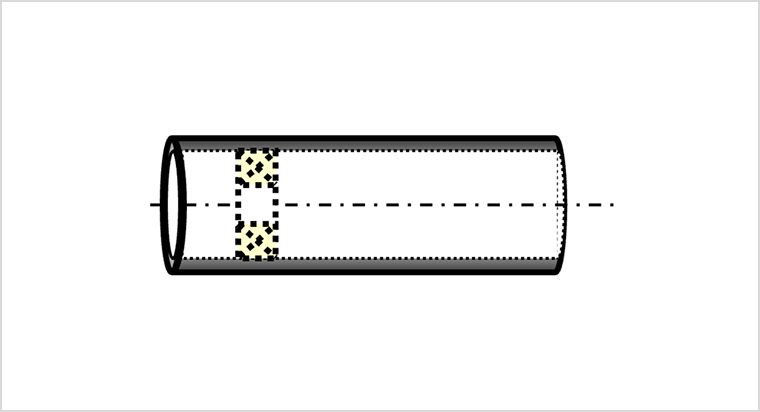

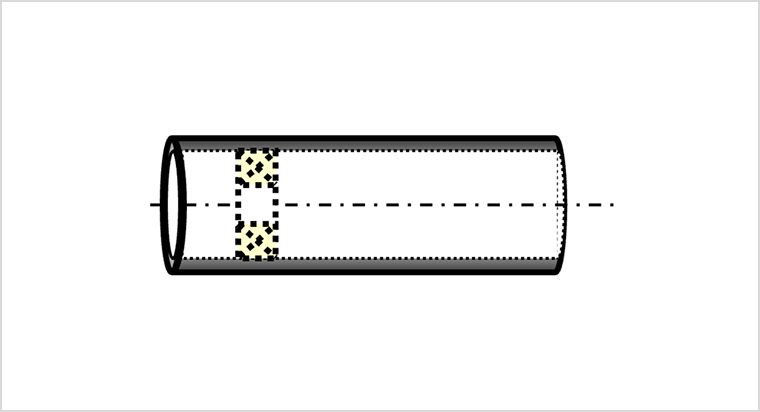

- Insert ET

The probe passes inside of the test specimen

- Top placing ET

The probe is placed on the test specimen

Product Lineup

- Penetrating ECT System

ECT System for Steel Pipe (Through type)

This is an eddy current equipment that can be used for simple shapes such as wires and pipes. It is capable of detecting defects in the circumferential direction (T direction).

Features

- Excellent detecting accuracy is realized due to improvement of S/N by the effect of magnetic saturation device

- Fast inspection

- Marking control number or NG mark on the pipe (Option)

- In-line automatic ECT system to fit existing production line can be designed

Use

- Inspection of outside surface of pipe

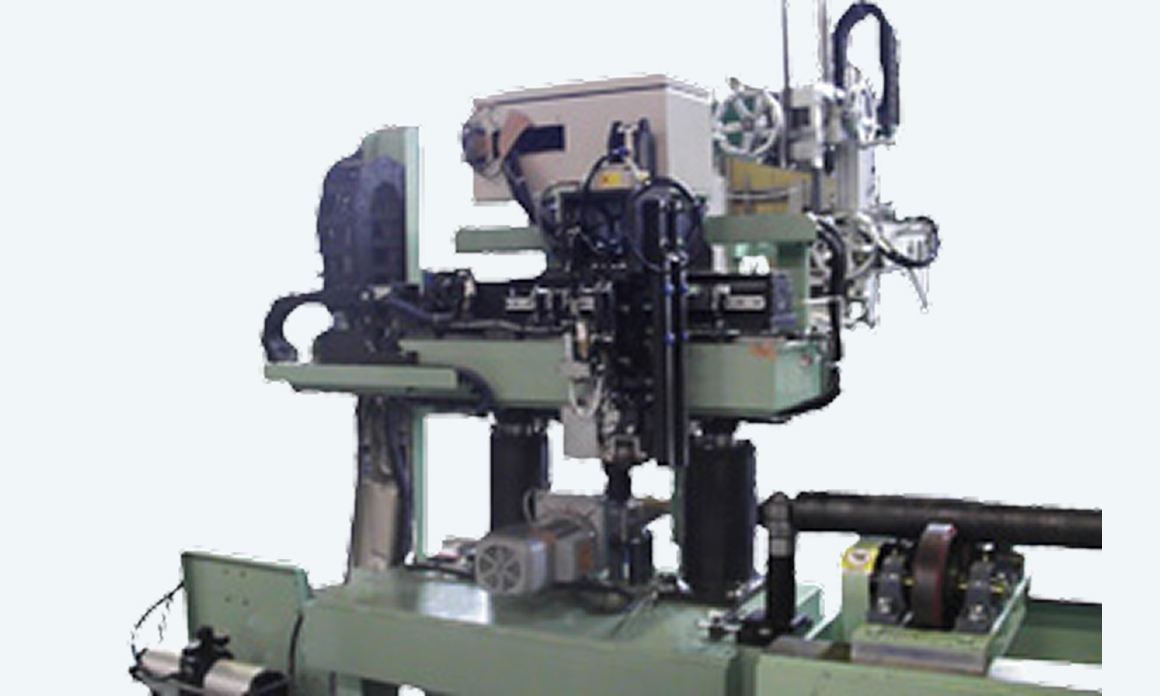

- Pipe ECT System (L)

ECT System for Steel Pipe End (Type L)

This is eddy current equipment that uses MARKTEC’s unique probe to detect defects in the axial direction (L direction) of pipe ends.

Features

- Using MARKTEC original theta probe, accurate inspection with large lift-off

- Fast inspection (during pipe turning at peripheral speed 60 m/min.)

- Paint shot NG marking on the pipe (Option)

- In-line automatic ECT system to fit existing production line can be designed

Use

- Inspection of flaw on surface of pipe end(longitudinal flaw)

- Air Float Probe ECT System

Fully Automatic ECT System for Cylinder Block

The Air Float Probe® type eddy current detection system uses a special attachment that floats the detection probe using air pressure, achieving non-contact, high-precision tracking.

Features

- Detecting probe does not contact with workpiece, therefore does not wear

- All directional flaw inspection can be done by one probe

- Paint shot NG marking on the pipe (Option)

- In-line automatic ECT system to fit existing production line can be designed

Product Column

Well-understood course

A Course to Better Understand Eddy Current Testing

Testing method using electro-magnetic induction is generally referred to as “Electro-magnetic Testing Method”, and for the purpose of detecting surface and subsurface flaws it is called Eddy Current Testing Method (ECT).

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30