Dye penetrant testing

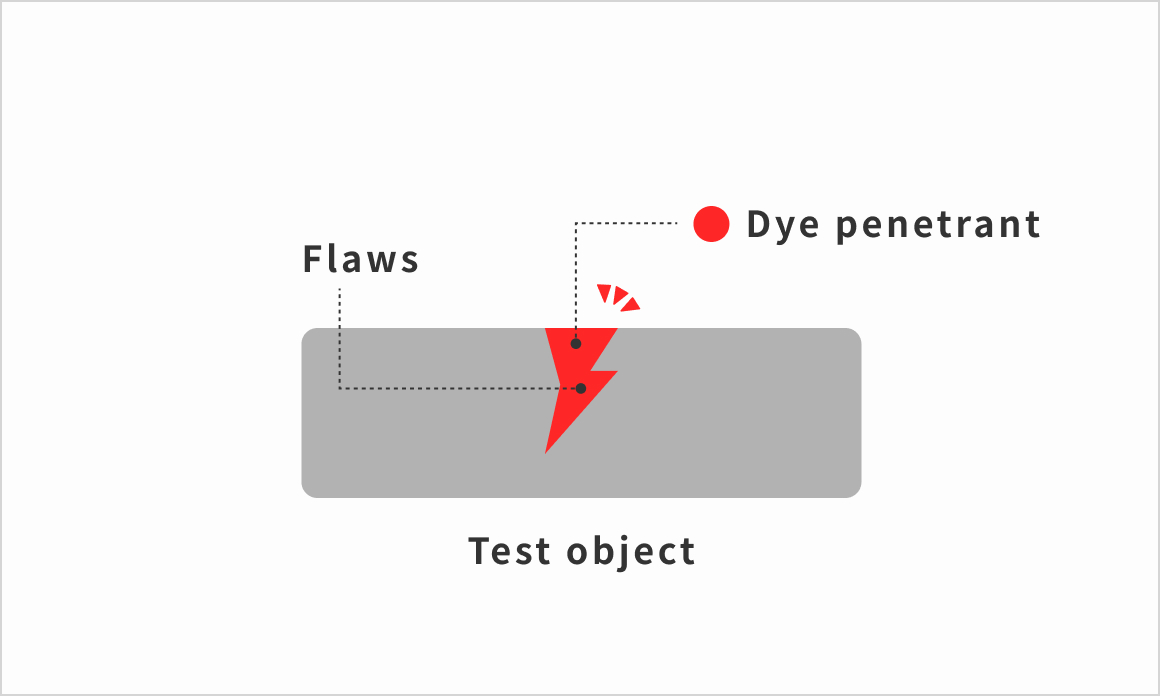

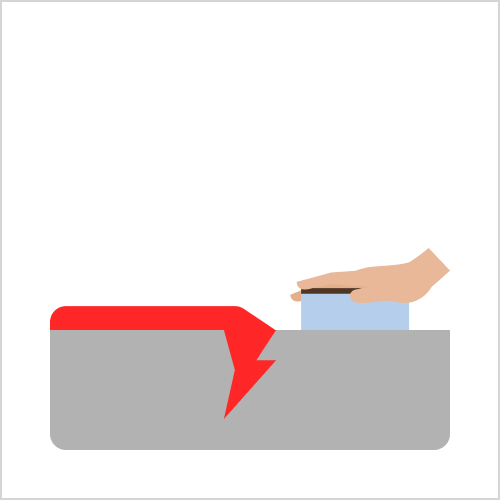

Dye penetrant testing (Dye PT, DPT) is a method to find fine flaw openings on the surface of the test specimen by impregnating a red liquid into them to enlarge the flaw.

No inspection equipment is required, and testing is possible by the using the three following liquids. “Penetrant” “developing agent” and “cleaner/remover”.

Materials covered in the testing

- Metallic and non-metallic material

Products used

- Flaw detection material

Features of testing

feature

Flaw detection is possible even for metallic and non-metallic materials if they are not affected by flaw detection materials and have no hygroscopic property

feature

It is easy to apply even to complicated test specimens as flaw detection materials are liquid

feature

It is possible to conduct the testing regardless of indoor or outdoor if it is a bright area

feature

No equipment is required, and testing is possible by the using the three following liquids. “Penetrant” “developing agent” and “cleaner/remover”. (Removing solvents)

Flow of flaw detection

The dye penetrant testing is generally conducted by the following procedure.

①Pretreatment

②Penetration treatment

③Penetration treatment

④Development

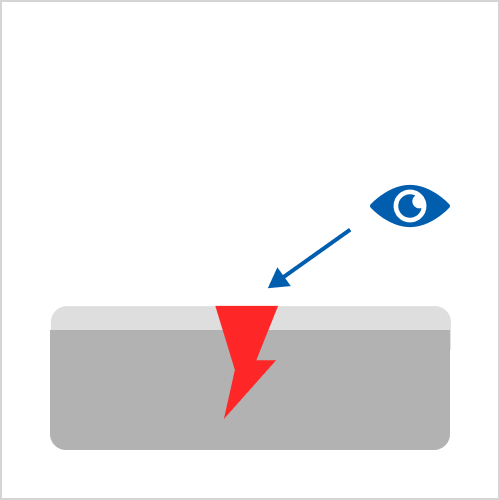

⑤Examination

Flaw detection material lineup

You can choose from the following three types of products for use in dye penetrant testing depending on the application and material.

Standard type

Low halogen and low sulfurtype

Non-dangerous goods type

Method | Name of combination products | Compatible with JIS | Compliance with ASME | Features | |

|---|---|---|---|---|---|

Method C |

Super Check UP-ST(J) | ✓ | Standard type suitable for detecting flaws on any ferrous and nonferrous metals. Optimum for partial examination on a large structure or weld, because no special equipment is required. UR-ST·M: Safer type with higher flashing point UD-ST·V: Ultra quick-drying type suitable for low temperature and high humidity | ||

Super Check UR-ST | ✓ | ||||

Super Check UR-ST・M | |||||

Super Check UD-ST | ✓ | ||||

Super Check UD-ST・V | ✓ | ||||

Method A |

Super Check P-GⅢ(EXP) | Water washable penetrant suitable for detecting flaws on nonferrous metal materials, ceramics, and large test pieces. | |||

Super Check UD-ST | ✓ | ||||

Super Check P-GⅢ-NII | Water washable penetrant suitable for detecting flaws on slabs, large test pieces, and small mass-produced test pieces. Applicable to testing components with complex shapes. | ||||

Super Check UD-ST | ✓ | ||||

Super Check UD-ST・V | ✓ | ||||

Method C |

Eco Check EP-ST(J) | ✓ | Standard-type ecological penetrant suitable for detecting flaws on any materials such as metallic and non-metallic materials. | ||

Eco Check ER-ST | ✓ | ||||

Eco Check ED-ST | ✓ | ||||

Method A Water washing |

Eco Check EP-W(J) | ✓ | Ecological-type water washable penetrant made from natural materials and cosmetic materials, friendly to living things and the environment | ||

Eco Check ED-ST | ✓ | ||||

Method | Name of combination products | Compatible with JIS | Compliance with ASME | Features | |

|---|---|---|---|---|---|

Method C |

Super Check UP-T(J) | ✓ | ✓ | Low halogen and low sulfur penetrant suitable for detecting flaws on stainless steel, titanium alloys, and nickel alloys.

| |

Super Check UR-T | ✓ | ✓ | |||

Super Check UR-T・M | ✓ | ✓ | |||

Super Check UD-T | ✓ | ✓ | |||

Super Check UD-T・V | ✓ | ✓ | |||

Method A |

Super Check UP-GⅢ・T(J) | ✓ | ✓ | Low halogen and low sulfur penetrant suitable for large objects made of stainless steel, titanium alloys, nickel alloys, or objects with a rough surface.

| |

Super Check AS-T | ✓ | ✓ | |||

Super Check UD-T | ✓ | ✓ | |||

Super Check UD-T-V | ✓ | ✓ | |||

Method C Removal of solvent |

Eco Check EP-T(J) | ✓ | ✓ | Low halogen and low sulfur penetrant suitable for detecting flaws on stainless steel, titanium alloys, and nickel alloys Ecological type friendly to living things and the environment

| |

Eco Check ER-T | ✓ | ✓ | |||

Eco Check ED-T | ✓ | ✓ | |||

Eco Check ED-T-V | ✓ | ✓ | |||

Method | Name of combination products | Compatible with JIS | Compliance with ASME | Features | |

|---|---|---|---|---|---|

Method C |

Super Check UP-NU-H | ✓ | Penetrant which is non-hazardous, not subject to the Fire Defense Law, and incombustible, and which removes solvent | ||

Super Check UP-NU-H | ✓ | ||||

Super Check UP-NU-H | ✓ | ||||

Method A Water washing |

Super Check P-LK | Water washable and incombustible penetrant suitable for detecting flaws on slabs or large test pieces Applicable to testing components with complex shapes.

| |||

Super Check UP-GⅢ・W | |||||

Super Check D-LW | |||||

Super Check D-LW-K | |||||

Super Check D-LW-N | |||||

* This flaw detector can also be used in Method A: Water rinse. In this case, use AS-T as the cleaning agent/remover.

Product information for

Dye Penetrant Flaw Detection Material

can also be found in the catalog.

Product details

- Dye Penetrant

- Cleaner/Remover

- Developer

Super Check

MARKTEC’s dye penetrant flaw detection material is popularly known as “Super Check.” We offer aerosol and canned products depending on the application and purpose.

- Dye Penetrant

- Cleaner/Remover

- Developer

Eco Check

Based on our original ecological concept, we pursue safety for humans and the environment, and use natural materials and cosmetic materials for this visible dye penetrant product.

Related products

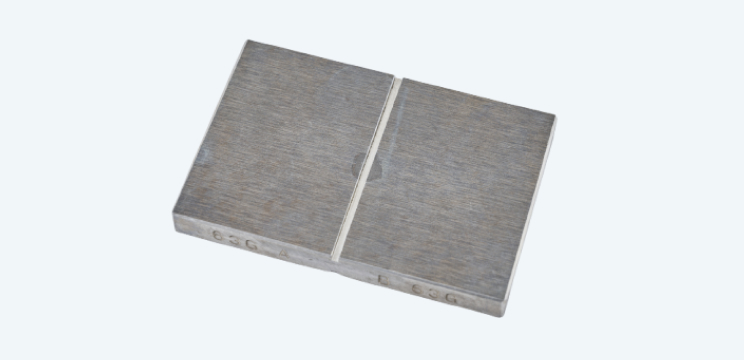

Test pieces for magnetic particle testing (link destination)

They are used for checking the strength and direction of the magnetic field on the testing surface, performance inspection of flaw detection equipment and inspection liquid, checking the effective range of flaw detection and conditions of flaw detection, etc.

Product Column

About designated quantities

in the Fire Service Law

Non-destructive testing・Printing and marking

About designated quantities in the Fire Service Law

A Course to Better Understand Penetrant Testing

Well-understood course

A Course to Better Understand Penetrant Testing

Non-destructive testing・Printing and marking

About treatment of wastewater after flaw detection testings

Non-destructive testing・Printing and marking

Test pieces for penetrant testings

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30