What is Non-destructive testing?

Non-destructive testing is a technique to find out fine defects without breaking parts, etc. to prevent accidents before they happen.

Non-destructive testing is a technique to find out fine defects without breaking parts, etc. to prevent accidents before they happen.

It plays an important role at various sites of quality control such as automobile, railway, aircraft, bridge, power plant, chemical plant, etc.

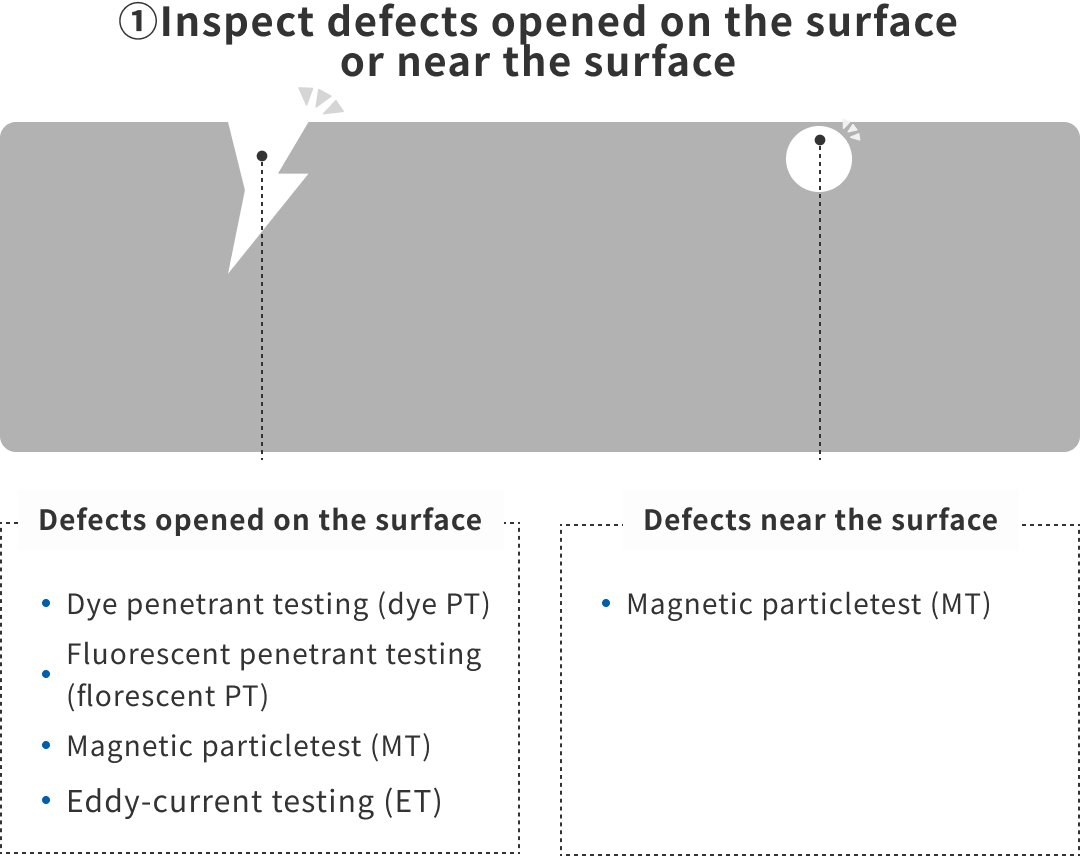

Meanwhile, there are various methods for the non-destructive testing.

Please refer to the information below, as the suitable inspection method varies depending on type of defect and material, etc. desired for inspection.

If you are not sure, please feel free to contact us.

Test Methods for Surface Defects

Test method | Types of defect | Materials covered in the testing | Features | Necessary items |

|---|---|---|---|---|

PT Dye penetrant testing |

|

|

|

|

PT Fluorescent penetrant testing General For the aircraft industry |

|

|

|

|

MT Magnetic particle testing |

|

|

|

|

ET Eddy-current testing |

|

|

|

|

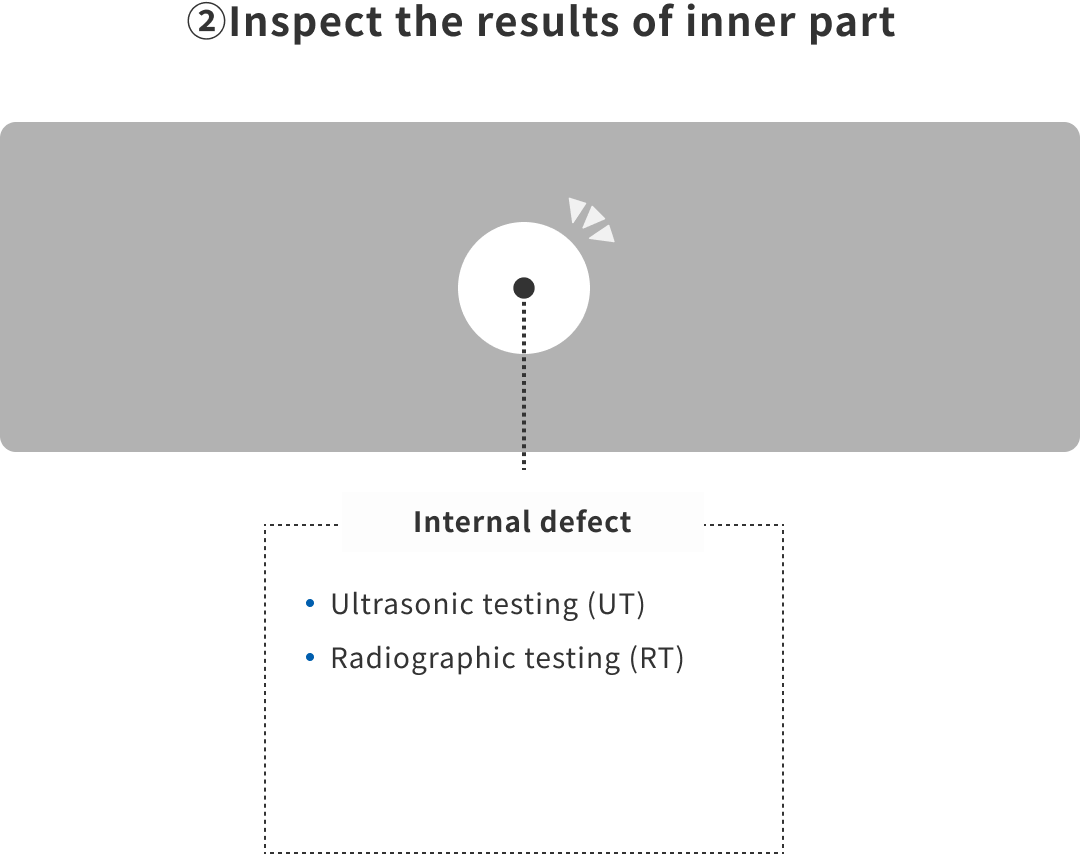

Inspection method for internal defects

Test method | Types of defect | Materials covered in the testing | Features | Necessary items |

|---|---|---|---|---|

UT Ultrasonic testing |

|

|

|

|

RT Radiographic testing |

|

|

|

|

Product Lineup

PT

Dye penetrant testing

PT

Fluorescent penetrant testing (general)

PT

Fluorescent penetrant testing (for the aircraft industry)

MT

Magnetic particle testing

ET

Eddy-current testing

Related products

- Dye Penetrant

- Cleaner/Remover

- Developer

Super Check

MARKTEC’s dye penetrant flaw detection material is popularly known as “Super Check.” We offer aerosol and canned products depending on the application and purpose.

- Dye Penetrant

- Cleaner/Remover

- Developer

Eco Check

Based on our original ecological concept, we pursue safety for humans and the environment, and use natural materials and cosmetic materials for this visible dye penetrant product.

- Cleaner/Remover

- Developer

- Fluorescent penetrant

Super Glo

Super-Glo is standard fluorescent penetrant flaw detection material. The rich and varied lineup provides penetrants that are optimal for a wide range of applications and purposes.

- Fluorescent penetrant

Eco Glo

Eco-Glo is an ecological penetrant with main components that are safe for people and the environment. It maintains all the penetrating performance of standard penetrant while also providing improved wastewater treatment and washing performance.

Fluorescent penetrant equipment

- Remover

- Emulsifier

- Developer

- Fluorescent penetrant

Super Glo (AMS 2644 certified product)

Super-Glo is standard fluorescent penetrant flaw detection material. The rich and varied lineup provides penetrants that are optimal for a wide range of applications and purposes.

Fluorescent penetrant equipment

- Fluorescent magnetic particle

- Nonf luorescent magnetic particle

- Water-soluble magnetic dispersant

- Magnetic particle dispersing oil

- Water-soluble anti-rusting agent

- Water-soluble defoaming agent

Super Magna

The standard for magnetic particle inspection. We have a lineup of various types of products and can offer the best solution for your application.

- Fluorescent magnetic particle concentrated solution

- Dispersant

Eco Magna

Friendly to living things and the environment. The magnetic particle solution can be easily prepared. User-friendly fluorescent magnetic particle concentrated solution has appeared on the market.

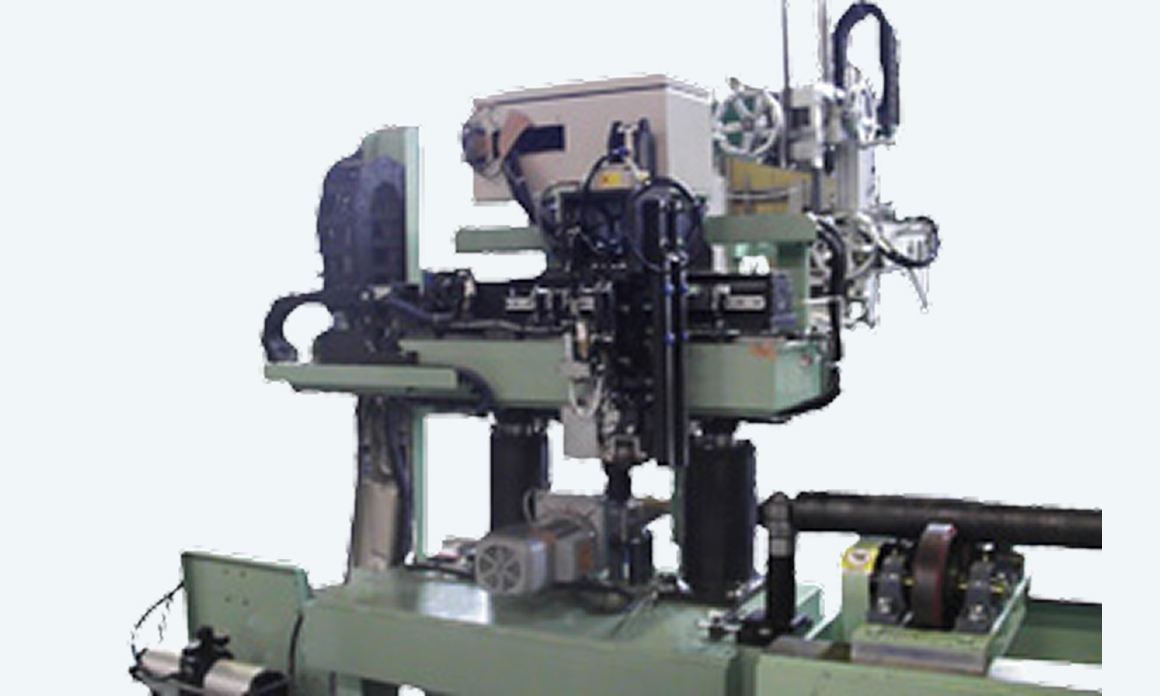

Magnetic particle equipment

Introduction of magnetic particle equipment is common in the case of mass inspection of mass produced items, etc. MARKTEC can propose magnetic particle equipment, including feeding, for castings and forgings of ferromagnetic materials (iron, etc.) and billets manufactured by steel manufacturers.

Eddy-current testing

It is possible to conduct automatic/mass inspections by introducing the eddy current flaw detection equipment.

Black light・UV intensity tester

MARKTEC’s black lights (ultraviolet flaw detection lights) are designed and fabricated under the most suitable conditions for flaw detection testings in which ultraviolet rays (UV-A) including 365 nm are irradiated.

Leakage inspection material

For leakage inspections, there are various kinds such as oil leakage, water leakage, air leakage, etc. MARKTEC can propose the leakage inspection materials suitable for applications.

Degreasing cleaner

In manufacturing sites, degreasing cleaners are used for degreasing cleaning of machines, removing adhesives, and so on. MARKTEC provides a lineup of degreasing cleaners for various applications.

Hardness Tester

MARKTEC offer a variety of equipment, including portable hardness testers, for on-site use.

Other Products

We also offer a variety of products, such as concrete testing agents and keggerants.