Product Description

MARKTEC’s custom-made printing devices for steel pipes include the one for small and middle diameter pipes (stationary type) which performs full automatic reciprocating printing on the outer surface of steel pipes and in the axial direction, the one for small and middle diameter pipes (traveling type) which performs automatic printing on the outer surface of steel pipes and in the axial direction, and the one for large diameter pipes (stationary type) which performs full automatic printing on the inside and outside surfaces of steel pipes.MARKTEC can propose custom‐made printing devices specialized for steel pipe manufacturers.

Features

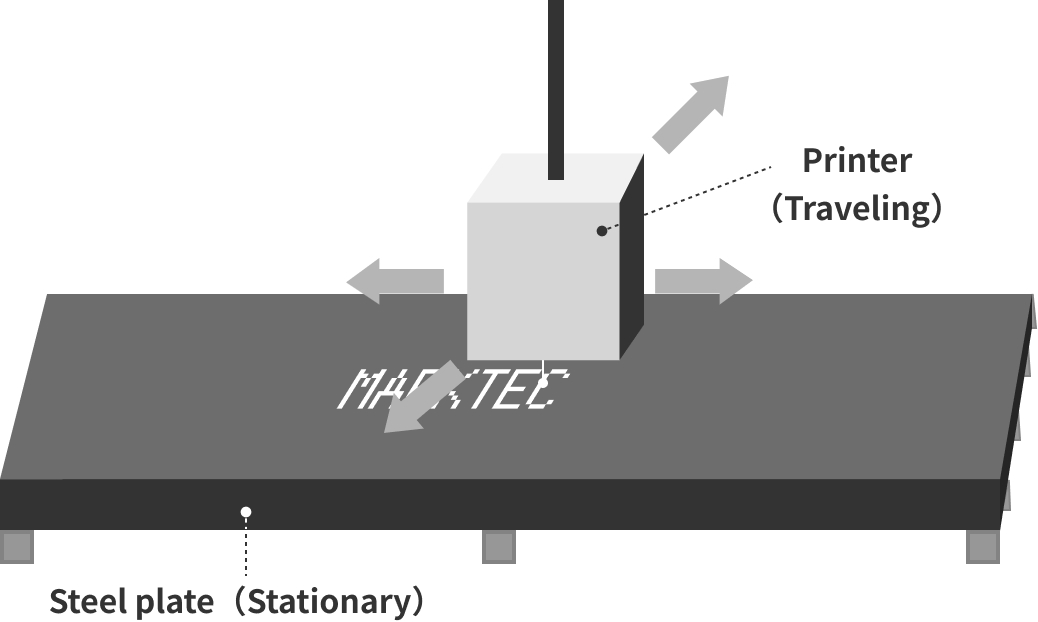

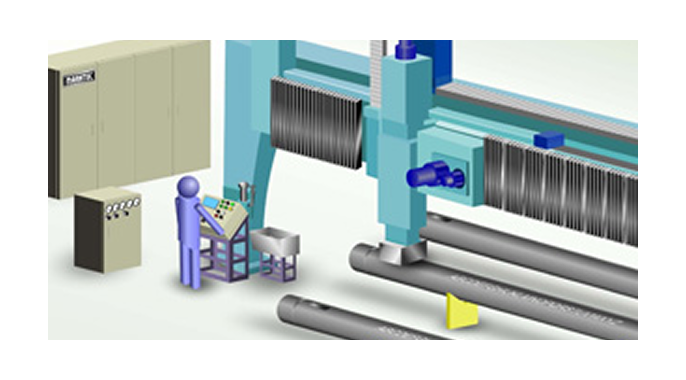

For small- and middle-diameter pipes (Stationary type)Features

feature

Marking is made with high quality and precision because the printer travels on the steel pipe in the stationary state.

feature

It is also possible to mark multiple lines or process marking on two to three steel pipes simultaneously by increasing printers.

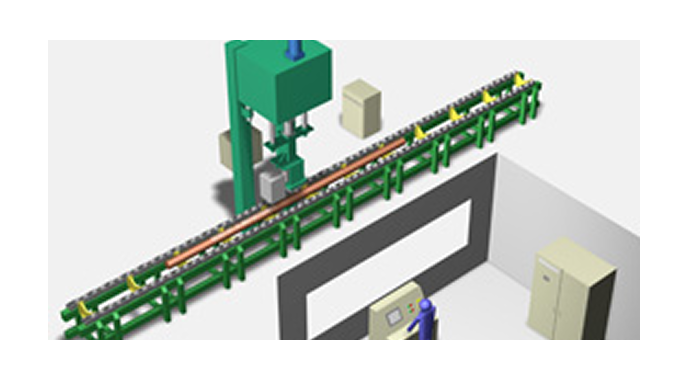

For small- and middle-diameter pipes (traveling type)Features

feature

Marking is done continuously at the pipe manufacturing line as marking is made while the steel pipe is traveling.

feature

It is also possible to mark multiple lines or process marking on two to three steel pipes simultaneously by increasing printers.

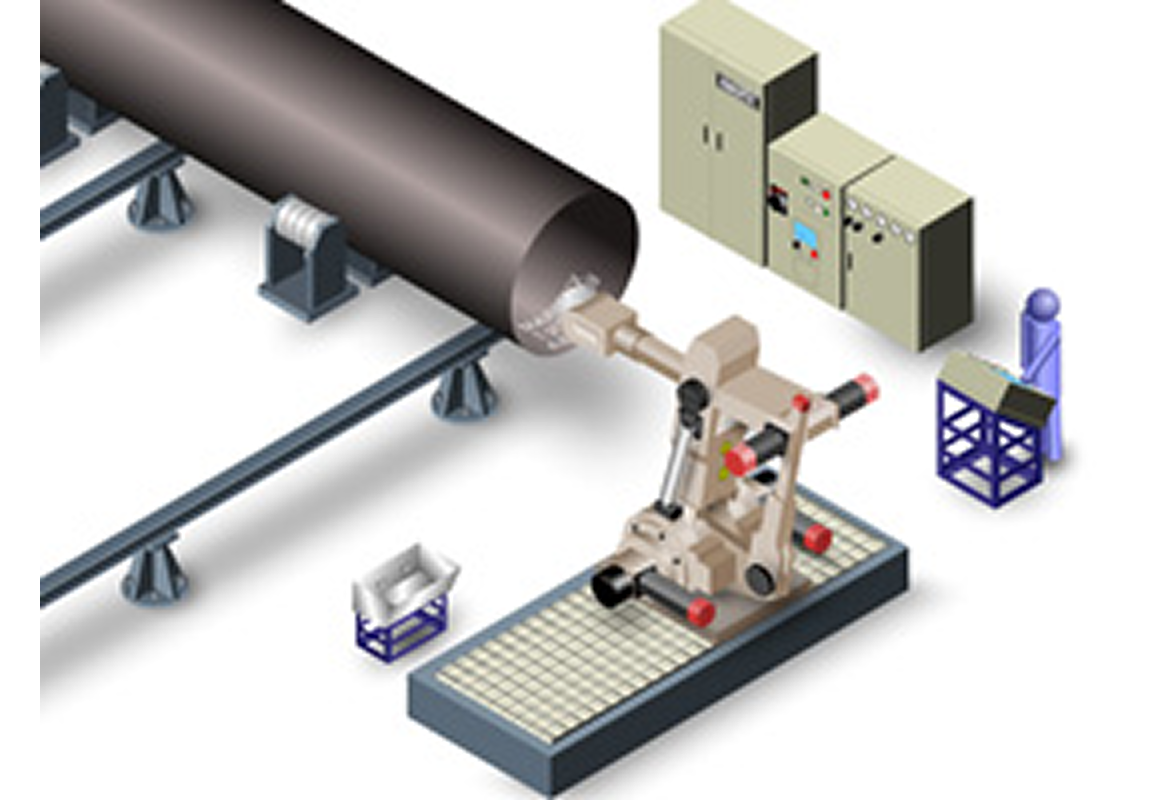

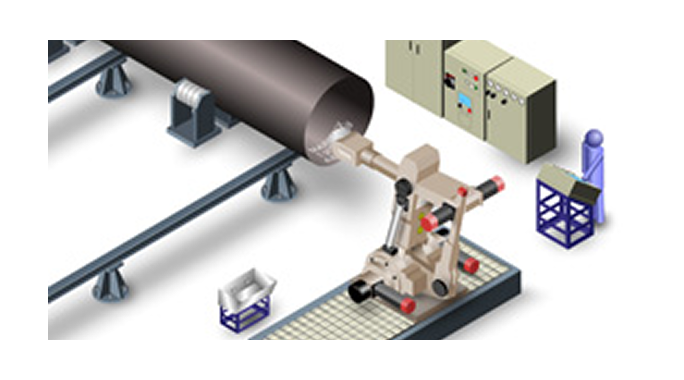

Features of the device for large-diameter pipes (Stationary type)

feature

Marking is done by using the 6-axis articulated industry robot and moving it along the inside and outside surfaces of the steel pipe.

Specifications

Product Specification

For small- and middle-diameter pipes (traveling type) | For small- and middle-diameter pipes (stationary type) | For large-diameter pipe | |

|---|---|---|---|

Device image |  |  |  |

Overview | Marking is possible along the steel pipe in full length. | Marking is possible along the steel pipe in full length. | Marking of up to 20 lines is possible to the circumferential direction on the inner and outer surfaces of steel pipe and to the longitudinal direction on the outer surface of steel pipe. |

Location | On the conveyance transfer line of the steel pipe finishing plant | Near the longitudinal feed conveyance line of the steel pipe plant | Near the conveyance line of the steel pipe finishing plant |

Pipe to be marked | Seamless pipe, ERW pipe | Seamless pipe, ERW pipe | Large diameter ERW pipe, Spiral pipe, UO pipe |

Outer Diameter | More than 27.0 mm | More than 27.0 mm | ー |

Marking Speed | Max. 45 m/min. | Max. 90 m/min. | ー |

Pipe Condition |

|

|

|

Installed Position | Above the transverse transfer table with V-shape holders | Before cutting: longitudinal transfer method with V-shape roller | ー |

Marking Specification |

|

|

|

Main standard equipment configuration | Marking Machine :

Drive unit for Marking Machine :

Control Equipment

| Marking Machine :

Drive unit for Marking Machine :

Control Equipment

| Marking Machine :

Multi Axial Robot

Control Equipment

|

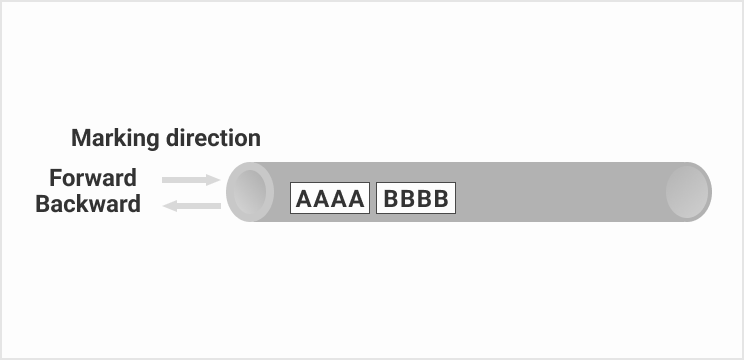

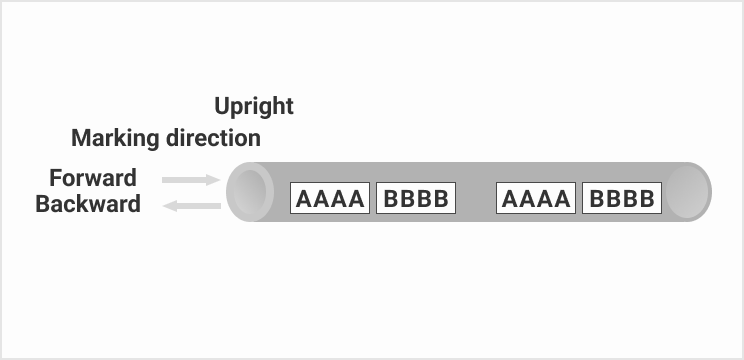

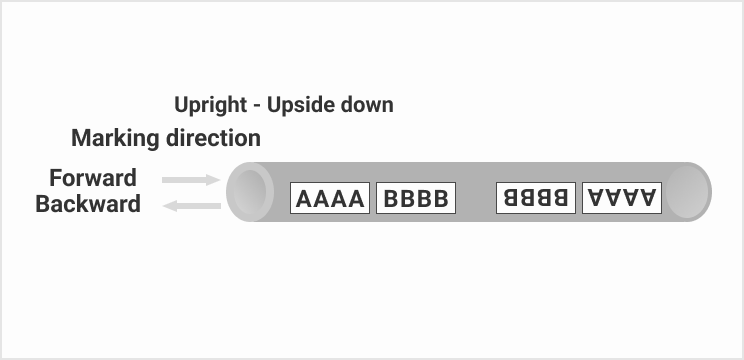

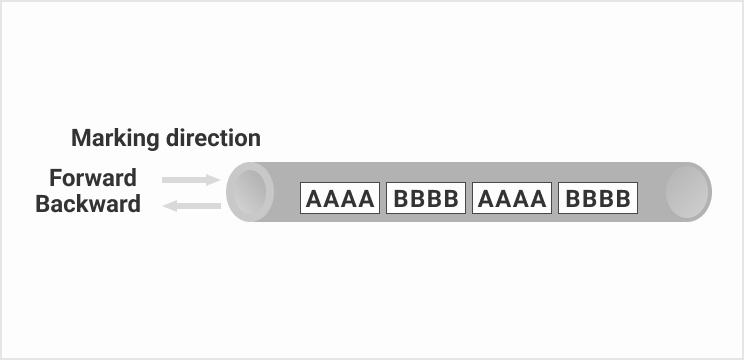

印字パターン

Single end marking

Double end marking

Double end marking

Repeat marking

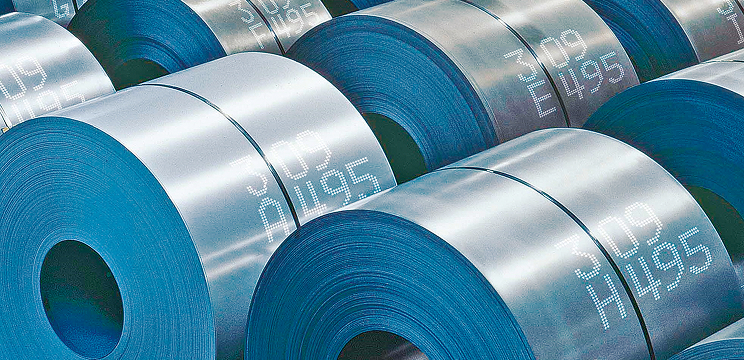

Marking examples

Printing Sample

Printing Sample

Related products

Paint

Tecmarker and Eco Color are the specialized paints for our printing and marking devices. We have a wide range of colors to suit a variety of applications.

contact

Inquiries about “製品“

For orders or inquiries about “製品“products,

please feel free to contact us via the email form or by phone.

Monday to Friday 8:45-17:30