- Well-understood course

A Course to Better Understand Penetrant Testing

- Non-destructive testing

So called PT (Penetrant Testing) or LPT (Liquid Penetrant Testing), this method can be applied to the surface flaw inspection of almost every materials and products irrespective of their stuff. When the “penetrant”, vivid colored or fluorescent, is applied to the surface to be inspected, it penetrates into the surface breaking flaw and the flaw is filled with the penetrant. Then filled penetrant will be taken up from the flaw by the “developer” applied and will spread around the flaw on the surface.

Inspector easily finds the flaw observing the taken up penetrant on the surface.

Penetrant testing products

Dye Penetrant Flaw Detection Material

・Super Check

・Eco Check

Fluorescent Penetrant Flaw Detection Material

・Super Glo

・Super Glo (AMS 2644 certified product)

・Eco glo

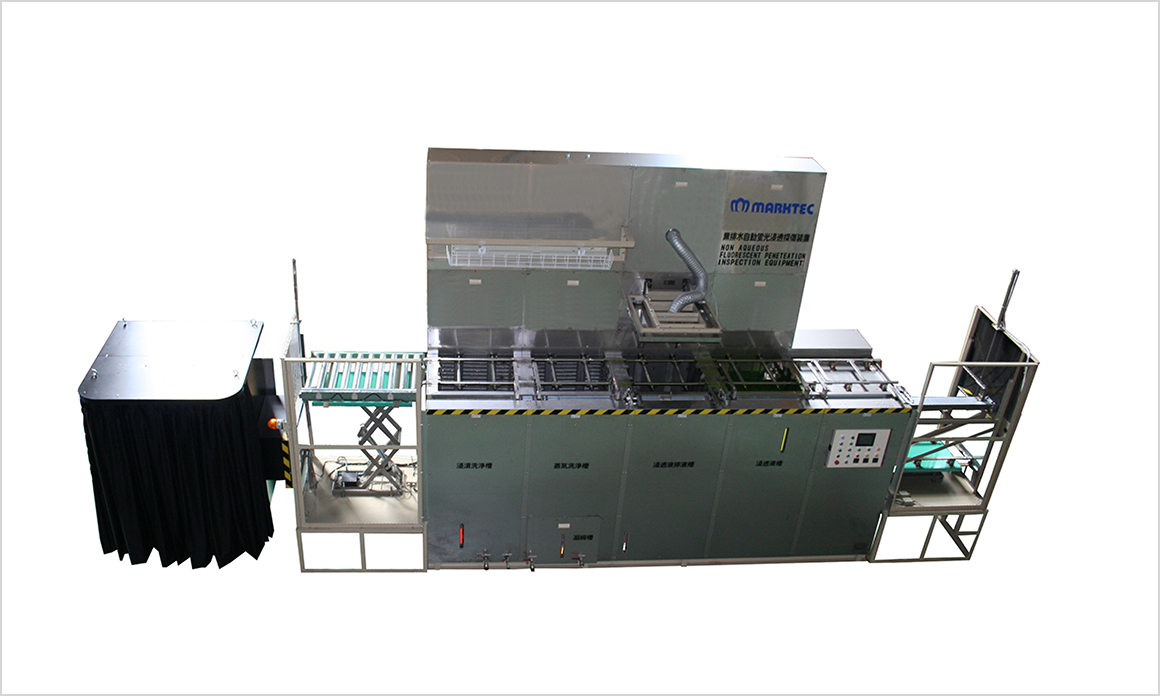

Penetrant Testing Unit

・Fluorescent Penetrant Inspection Unit

・No-Draining PT Unit

Procedure of PT

Procedure of PT is usually

“Pre-cleaning” – “Penetrating” – “Penetrant Removal (Washing)” – “Developing” – “Observation” – “Post-cleaning”.

STEP

Pre-cleaning

Dust, oil or other liquid on the surface to be inspected, that will prevent perfect penetration of penetrant into the flaw, is removed by petroleum solvent, organic solvent etc. before the penetrating process.

STEP

Penetrating

Penetrating is based on the rule called Capillary Phenomenon. Visible dye penetrant (vivid colored) or fluorescent penetrant is used for this process, that will penetrate into the surface breaking flaw.

STEP

Penetrant removal (Washing)

Excess penetrant on the surface will be taken off by the remover. The method of the penetrant removal varies depending on the type of the penetrant used.

STEP

Developing

The penetrant kept in the flaw is taken up by the developer and forms flaw indication on the surface.

STEP

Observation

The surface is visually observed and the flaw indication is identified.

Penetrant flaw detection materials

Penetrant (P), Developer (D) and Remover (R) are usually used for PT.

There are two types of PT method, those are Dye penetrant PT using visible dye penetrant flaw detection material and Fluorescent PT using fluorescent penetrant flaw detection material.

(1)Water washable penetrant

Since almost penetrant is oil based, it is difficult to wash it off by water. The water washable penetrant is emulsifier (surface-active agent) added penetrant in order to be water washable.

(2)Solvent removable penetrant

This is oil based penetrant and the organic solvent is used for removing excess penetrant.

(3)Post emulsifiable penetrant

This penetrant does not contain emulsifier. After penetrating, the emulsifier is applied to remove excess penetrant for water washing.

(4)Developing agent

The main component of the developer is an inorganic fine powder. There are dry developers used as is, wet developers suspended in water, and quick-drying developers where the powder is suspended in a solvent and filled into aerosol cans.

Various types of penetrant fluids and their applications

The table below shows the very general application range of penetrant testing using various penetrant agents.

Various types of penetrant fluids and their applications

| Items covered | Details of items | Water washable fluorescent penetrant | Post-emulsifiable fluorescent penetrant | Solvent-removable fluorescent penetrant | Water washable dye penetrant | Post-emulsifiable dye penetrant | Solvent-removable dye penetrant |

|---|---|---|---|---|---|---|---|

| Type and size of defect | Fine cracks, wide and shallow cracks | ✓ | ✓ | ||||

| Very narrow cracks such as fatigue cracks and grinding cracks | ✓ | ✓ | |||||

| Test specimen | Small mass-produced parts, sharp corners such as screws and keyways | ✓ | |||||

| Test items with rough surfaces | ✓ | ✓ | |||||

| When detecting flaws in parts of large parts or structures | ✓ | ✓ | |||||

| Environmental conditions | When it is not feasible to make the test area dark | ✓ | ✓ | ✓ | |||

| When there is no water supply or electrical equipment | ✓ |

Source: “Non-destructive Inspection Technology Series” compiled by the Japan Society for Non-Destructive Inspection

Penetrant Testing (1989), P-9, Table 1-1